Resolving Core Machine Catalyst System Problems

Core machines are at the heart of many metal casting operations, and when they’re running well, production usually follows suit. But sometimes the smallest part of the system ends up causing the biggest headaches. That’s often the case with catalyst systems. A weak flow, inconsistent output, or a clogged line can throw off the entire process, causing delays or poor-quality castings. If issues with the catalyst system aren’t spotted early, it can mean more maintenance, lost time, or worse—faulty products.

It helps to know what to look for and what steps to take when things start going sideways. Whether you’re running a cold box process or working with a more custom machine setup, the basics of diagnosing and resolving catalyst problems stay the same. By understanding what these systems do, what typically goes wrong, and how to manage the fix, you can keep downtime to a minimum and quality consistently high.

Understanding Core Machine Catalyst Systems

Catalyst systems within core machines play a major role in forming strong, accurate sand cores. In cold box processes, the catalyst is typically a gas, usually an amine, that triggers a chemical reaction to harden the resin-coated sand. It’s the final curing agent that locks everything into place and keeps core integrity intact during the casting process. When the catalyst flow is steady and well-calibrated, casting outcomes stay predictable.

But plenty of variables can throw things off. Maybe moisture in the air affects gas performance. Maybe a worn seal starts leaking. Or maybe a build-up in the lines causes a slow delivery. Small inconsistencies in pressure or timing can spiral into larger problems. When the catalyst doesn’t distribute properly, curing becomes uneven. That leaves you with soft cores, distorted forms, or in some cases, cores that crumble during metal pour.

Some of the more common catalyst-related problems include:

– Gas flow disruption due to clogged or corroded lines

– Imbalanced catalyst-to-resin ratio, often caused by supplier inconsistencies or faulty mixing units

– Uneven distribution of gas across the core box, leading to partial curing

– Timing delays in purge cycles that interrupt the curing sequence

A single fault in any of these areas can mean scrapping cores or halting production until it’s resolved. Troubleshooting early and consistently can prevent many of these problems from turning into disasters. But before a fix can work, you need a clear grasp of what usually fails and why.

Identifying Common Catalyst System Problems

Spotting a catalyst system problem usually starts with the cast product. Defects in cores may look different from each other, but they often point to familiar faults in the curing process. Uneven hardening, surface crumbling, or soft spots in finished cores are often reliable red flags. And if you’re seeing incomplete sand flow or resin pooling, it might not be the molding process. It could be the gas system that’s out of sync.

Here’s a closer look at some of the most frequent issues that show up with catalyst systems:

1. Inconsistent Catalyst Delivery

Unreliable catalyst flow can mean the difference between a solid core and one that falls apart on removal. Causes may include incorrect gas pressure, lagging control valves, or line contamination from moisture or particles.

2. Clogged or Dirty Lines

Over time, catalyst plumbing can develop internal build-up. This is especially true if purging routines aren’t maintained or if environmental conditions fluctuate. Even a partial blockage can reduce the effectiveness of the catalyst and lead to only part of the core curing.

3. Incorrect Catalyst-to-Resin Ratio

If this ratio is off, even slightly, you may see over-cured surfaces that are brittle or under-cured interiors that are too soft. This issue can stem from faulty metering pumps or injector wear.

4. Irregular Distribution

When the gas doesn’t spread evenly throughout the core box, the result is inconsistent hardness across the core. This might be due to port misalignment, clogged vents, or even poor box design.

5. Timing Errors

If the purge cycle gets out of sync with the catalyst injection, resin may start curing too late or too early. Fixing this usually involves recalibrating your control system’s delay settings or checking the sequence programming.

These problems don’t always show clear warnings, so routine checks and a trained eye go a long way. It’s not just about fixing a problem when it happens. It’s about recognizing early signs so it doesn’t turn into something bigger down the road.

Steps to Diagnose Catalyst System Issues

When your core machine output starts showing signs of trouble, the best place to start is the catalyst system. Diagnosing early helps avoid larger disruptions. A step-by-step approach helps narrow things down without having to disassemble the entire line.

Start with a visual inspection. Look for signs of wear, leakage, or buildup near the gas lines, valves, and nozzles. If there’s residue on the fittings or stains near seals, that’s a sign something is off. Next, check pressure gauges. A sudden drop or uneven pressure across different points in the system can point to blockages or faulty regulators.

Watch the timing and performance of the purge and injection phases. Compare actual behavior to what’s set in the system. Mismatches often mean that controls or sensors need recalibration. Run a dry test to confirm all valves open and close on command. Unresponsive valves could mean problems with the control board or worn actuators.

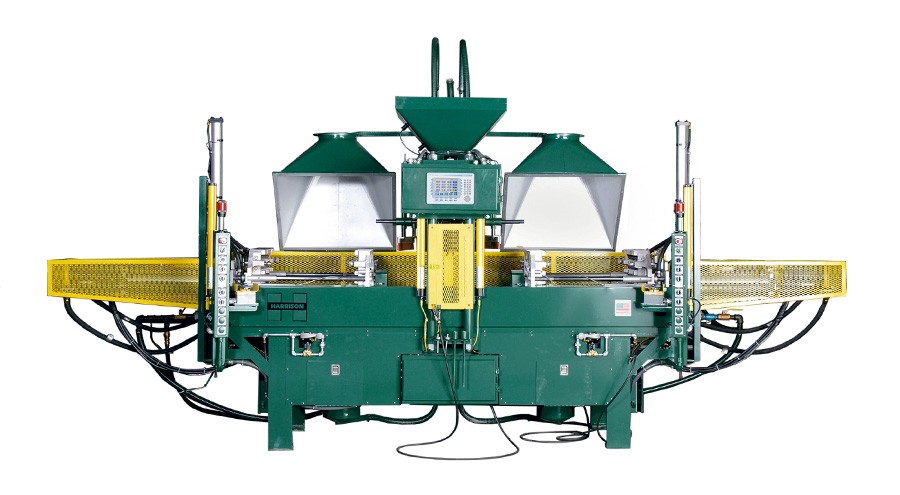

It’s also smart to monitor catalyst consumption. If usage suddenly changes and your production rate hasn’t, it could mean you have a leak or a faulty metering setup. Use a flow meter when possible. These readings help verify whether the correct amount of catalyst is reaching the core box. Keep an eye on delivery across stations in machines like dual station cold box units, where uneven flow can mean inconsistent product strength.

Helpful tools and techniques include:

– Inline filters for detecting particle contamination

– Thermal imaging to spot heat loss in lines or valves

– Digital pressure and flow sensors for real-time logging

– Manual leak detectors or soap tests at fitting joints

– Diagnostic codes on integrated touchscreen controls

Make time each week or per shift for quick checks if you’re using high production machines. Tracking even small changes helps catch problems before they get worse. Regular troubleshooting habits can save hours of lost output.

Effective Solutions for Catalyst System Problems

Once you’ve pinpointed the issue, it’s time to address it. Sometimes it’s just a cleaning job, other times you’ll need to replace a part like a valve, line, or fitting. Fixing the root cause—not just the symptom—is what prevents the problem from coming back.

Cleaning internal lines, especially in machines that run long cycles or are in dusty areas, often clears up flow issues. Follow the purge settings and cleanout steps listed in the machine manual. Skipping cleanings when performance slips can leave buildup to grow. Small pieces of debris or moisture can creep in fast, especially with seasonal air changes.

If cleaning doesn’t do the job, replace suspect parts one by one. This means injector tips, regulators, and tubing. When curing is off in multi-station machines, compare sensor readings across each station to find the one that’s out of line. Machines like QuickCore or dual station cold box units often benefit from these kinds of station-specific checks.

Incorrect catalyst-to-resin ratios need attention too. Calibrate your metering pumps or swap them out if needed. Do this when shop temperatures are stable. Misfiring controls may be tied to wiring or sensor errors, so confirm connections before diving into code fixes.

Tips to improve long-term delivery and ratios:

– Swap out filters on a steady schedule

– Store catalyst in dry, sealed containers

– Keep extra tubing, seals, valves, and sensors on hand

– Update machine software when patches are released

– Benchmark new output data from prototype and mainline units

Doing a thorough job the first time saves downtime later. A pressure failure in a molding setup, such as with an automatic matchplate machine, could sideline output for hours. Getting proactive about these fixes benefits the entire team and your daily cycle flow.

Preventive Measures to Keep Catalyst Systems Running Smoothly

Stopping issues before they start is always better. Routine maintenance helps avoid unexpected downtime. Consistent performance doesn’t require complicated technology. It comes from habits and tracking what works.

Start with pressure monitoring. Log your expected ranges and compare results at the start and end of shifts. Big changes usually hint at developing issues. Keep systems tightly sealed and catalyst stored clean and dry.

Maintenance like line flushing, filter changes, and nozzle inspections should follow machine hours and sand use, not just the calendar. Machines with detailed curing cycles, such as 3-IN-1 models, may need more frequent care due to varying process loads.

Here’s a quick list of maintenance checks:

– Inspect gaskets and hoses for leaks or cracks

– Cycle purge valves twice daily

– Measure temperature and humidity near storage areas

– Clear vent ports on the core box often

– Review meter or sensor logs for slow declines in flow or pressure

Start a logbook for catalyst usage per batch and track core production rates. Small trends in this data often highlight bigger problems before they show up at scale. This is helpful for operations that use different resins or alternate molding setups like Osborn matchplate or manual machines.

How Consistent Catalyst System Management Pays Off

Solving problems early is good. Preventing them altogether is even better. A well-managed catalyst system means better casting results, less rework, and smoother handling across your whole operation. Even the most advanced cold box machines perform better when chemical inputs stay consistent.

Consistency is everything. Machines like vertically-horizontal parted core units or automatic flaskless molding machines are geared for output scale. But their tight tolerances make them extra sensitive when curing goes sideways. Don’t ignore small hiccups. A clean, balanced catalyst feed means fewer delays and better quality in every run.

Less downtime means smoother schedules and more predictable cycles. Spot failures before they affect batches and you’ll gain more control without extra costs. Know how your system should look, sound, and behave. Keep it monitored and maintained. And if something seems off, take action early before it turns into a full stop.

That simple mindset can make your casting operation more stable, more productive, and easier to manage for everyone on the floor.

Keeping your sand core operations consistent starts with staying ahead of small issues before they turn into production downtime. If your team is looking to improve reliability and streamline output, understanding how to maintain and troubleshoot core machines can make a big difference. EMI offers practical solutions to keep your foundry running smoothly across every shift.