QuickCore Machines and Faster Winter Startups Explained

Getting back up to full speed after the holidays is never easy in a foundry. The colder it gets, the more stubborn the equipment can be. Slow resin flow, freezing control lines, longer cure times, it all adds up to delayed cycles. That lag can throw off even the best-run floor when winter startup hits.

That’s where fast response core machines, like QuickCore, can really help. As we aim to jumpstart production in late January, these machines take less time to warm up and get moving. They reduce how long we spend troubleshooting and make early shifts more predictable. For shops trying to stay ahead of demand in cold weather, the right machine paired with smart planning can mean a smoother return to normal output.

Understanding QuickCore and Its Function

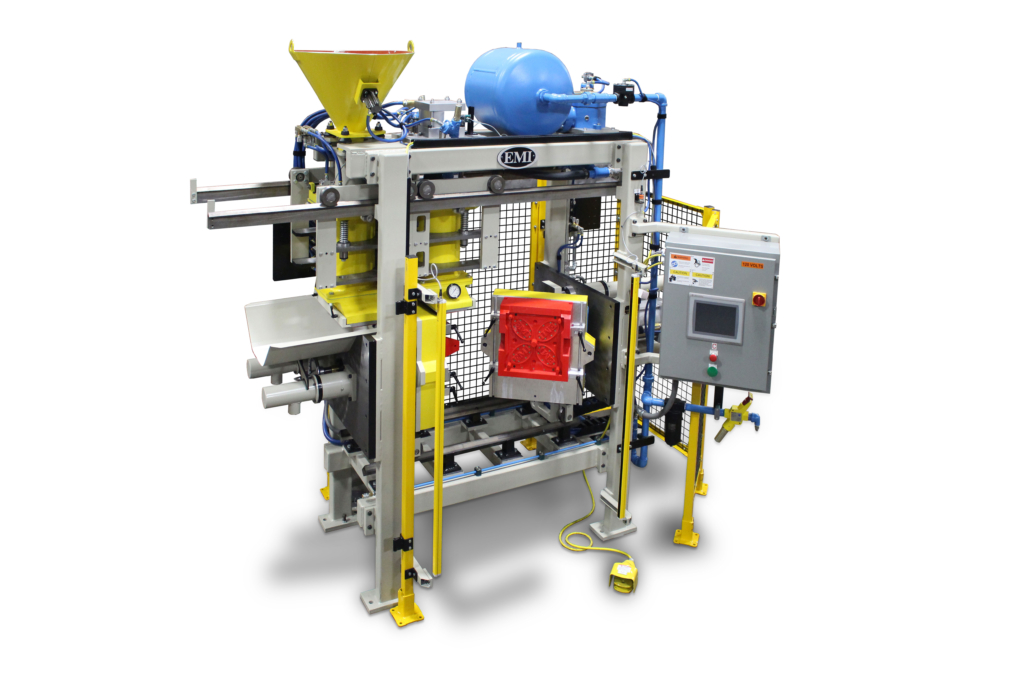

QuickCore is part of our Cold Box Core Machines line, but what sets it apart is its focus on simple, responsive output. Built around a vertically parted core box, it brings faster transitions between cycles and quicker setup when production ramps back up. That’s a big advantage when other equipment is fighting cold startup lag.

The vertically parted design helps in three ways:

- It reduces the number of moving parts that have to be recalibrated after cooldown.

- It allows shorter cycle times once the machine is running.

- It’s easier to maintain between job runs or when switching box layouts.

Compared to traditional core setups, which often require longer preheat times or extended flushing, QuickCore machines take less effort to prep for output. That makes them a good fit for teams that need to keep cold starts tight and controlled.

This adaptable design makes a difference in day-to-day workflow. Operators waste less time addressing alignment or calibration issues that happen after machines have cooled down, saving both time and energy. For shops that handle a variety of jobs or need to switch quickly between box layouts, this flexibility really helps. Switching to production mode is quicker, which lets foundry teams focus on staying ahead rather than resolving frequent startup problems.

How Cold Affects Equipment Startup

When winter sets in, problems tend to show up in the same places. We’ve seen sand blends become inconsistent and resin lines back up. Temperatures below freezing can cause curing to stall, resin flow to drop off, or valves to hesitate right when you need them to snap to.

Colder curing times affect:

- Final core quality and durability, especially in first-shift production.

- Timing between core readiness and mold sync, which leads to longer cycles.

- How much we need to rework or clean up after test runs.

When the environment in the shop cools significantly overnight, the effect on materials and machinery is even more noticeable. Sand that worked the day before suddenly clumps or won’t move, and resin that usually flows with no trouble might start to gum up or slow to a crawl. This extended curing time affects not just the quality of the first cores of the day but can also hold up the downstream process, making each job take a bit longer. The longer these delays last, the harder it becomes to stay on schedule and catch up by the end of the week.

If startup schedules creep forward every day, it doesn’t take long before a week’s worth of production needs catching up. That strain also creates more chances for part quality to slip, especially if crews rush to stay on track. Keeping machines that respond well in cold conditions can make the entire shift easier to manage.

QuickCore Features That Help in Winter

QuickCore machines are built with fewer steps between idle and active. That’s a big help when each degree of warmth matters. The design doesn’t rely heavily on extended warm-up routines or full recalibrations, which means we can avoid some of the common slowdowns of January and February.

Here’s how QuickCore helps:

- Minimal pre-config time after extended shutdowns.

- Simpler operator interfaces that don’t need layered restarts.

- Fewer sensitive flow paths that clog easily in low temps.

By having a straightforward interface, these machines make it easy for operators to get up and running. Instructions are clear, and settings return to the usual cycle much faster, even after weekends or long holidays when temperatures inside the plant are lowest. The reduced need for heavy recalibration lets workers focus more on monitoring for quality without breaking their workflow to troubleshoot technical issues.

Fewer sensitive flow paths also make maintenance easier. During winter, when fluids thicken and condensation can cause issues in hard-to-reach lines, having a design that avoids unnecessary complexity cuts down on problems. This advantage is magnified for smaller operations or prototype runs, where teams might not have as many people available to split time between production and maintenance tasks.

For smaller shops or those running limited prototype jobs during slower winter months, this kind of flexibility gives us more control. Instead of scheduling around what the machine needs, we can stick pretty close to our targets. Core production doesn’t stall while teams figure out what’s holding things up.

Reducing Setup Time Across Core Machines

Even with QuickCore’s help, we still prep our other systems to make sure production doesn’t hit bottlenecks. With a spread of core machines on the floor, everything starts easier when setups are standardized and routine work can move quickly.

Here are a few ways we cut down delays:

- Use shared interfaces or control panels, especially for legacy machines, so retraining in January is light.

- Group machines with similar part setups side-by-side for shared calibration checks.

- Schedule pre-tests or shorter runs right before startup week so we don’t wait on just one machine to clear the queue.

Having routine procedures and familiar interfaces for all machines means that anyone on the team can jump from one system to another without missing a beat. This is especially useful when winter weather has disrupted shifts or not everyone is available. Because operators aren’t fumbling with unfamiliar controls, each setup goes more quickly, minimizing lost time and keeping every piece of equipment running as intended.

Grouping machines together that serve similar jobs allows for efficient troubleshooting. Crews can check several units in one area without bouncing around the entire floor, keeping transition times down. When we plan a test run ahead of a big startup, we can catch minor issues before they become major sources of delay. These strategies mean less time catching up and more time producing what’s needed to hit targets.

None of this has to be complicated, but it does mean thinking a few steps ahead. We’re more likely to avoid lines that back up or heated resin systems that need to be flushed and tuned on the fly. That frees up the crew to focus on making quality cores, not stopping every hour to check another gauge.

Smarter Winter Starts Keep Schedules on Track

We’ve learned over the years that January doesn’t have to mean slow ramps and lost production days. When core machines are responsive and prepped right, we don’t lose time battling temp-related issues or start-of-year guesswork.

Using equipment like QuickCore gives us a strong start because we’re not stuck waiting on preheat windows or slow valve response. And when other machines on the floor are dialed in ahead of time, the entire shift moves more smoothly. That planning gives us more consistent cores, fewer failed cycles, and a better rhythm between mold and core systems across the day.

Settling into steady winter operation with responsive equipment helps keep employee morale higher, too. No one likes the pressure of scrambling to make up for lost time, and no one wants to see their hard work go to waste on cold start problems. With better planning and equipment choices, those rough January mornings become easy to handle. Everyone can look ahead, focus on quality, and keep things moving.

By thinking carefully about how winter affects our floor and making smart choices about both equipment and prep, we set ourselves up to run better, longer, and with fewer surprises no matter how cold the factory gets.

When a winter slowdown starts to impact cycle times or cause rework, it’s time to consider new strategies for prepping equipment for cold startups. Machines that respond quickly in low temperatures help us avoid morning slowdowns and keep production moving smoothly from the start. That’s why we rely on simple, reliable solutions designed to handle colder shifts. See how our core machines can support your operations, and contact EMI to discuss the best options for your facility.