Optimizing Production Schedules For Molding Machines

Keeping a steady and efficient production schedule for molding machines isn’t always easy. Foundries often deal with tight timelines, fluctuating orders, and pressure to meet quality benchmarks every shift. When schedules are built with gaps or imbalances, they can slow down cycles, cause panic workflows, or even lead to downtime that could have been avoided.

A better approach starts with rethinking how schedules are made. Fine-tuning production timing around machine capabilities and daily demands helps reduce unnecessary delays, smooth cycles, and improve overall mold quality. Whether you’re working with automatic matchplate machines, tight flask systems, or manual setups, having a schedule you can count on makes planning, staffing, and maintenance much easier to manage.

Assessing Current Production Efficiency

Before trying to fix your schedule, you need to understand where it currently stands. That might sound obvious, but many inefficiencies come from using old schedules long after conditions on the floor have changed.

Start by tracking daily output, mold rejection rates, and how much time machines sit idle between cycles. Watch for patterns in delays. If castings pile up before the pouring station or crews are constantly playing catch-up, something’s off in the flow.

Here are a few simple ways to spot where things bog down:

– Compare planned cycle times to actual output

– Review shift logs for recurring delay points

– Ask operators which machines tend to cause slowdowns

– Analyze timestamp data to log unexpected downtime

It’s not just about how fast a machine runs. An automatic matchplate machine might outpace a manual system, but if it breaks rhythm when running continuous jobs or needs frequent resets, that speed comes at a cost. Often, steady efficiency beats chasing bursts of output.

One foundry noticed its Savelli system seemed fine on paper. The cycles were fast, but cores weren’t arriving on time. After digging into the schedule, the issue turned out to be a lag during crew switchovers. They adjusted the shift transition and reclaimed lost minutes without altering machine settings.

Use insight like that to steer your focus. Fixing small operational routines or scheduling handoffs can often improve flow more than upgrading machinery. True efficiency comes from rhythm, not just pace.

Creating An Optimized Schedule

Once you’ve traced the points where timing slips, it’s time to build a smarter schedule that holds up on the floor. It should reflect real conditions, not just spreadsheet ideals.

A good schedule balances process times, machine capacity, staffing, and planned maintenance. Here’s a step-by-step way to think about it:

1. Group machines by type and output

Matchplate, tight flask, and manual operations don’t run the same way. Don’t overload slower machines just because faster ones finished earlier.

2. Align machine use with shift patterns

If two shifts are running different job types, stagger transitions so mold changes or pattern swaps fall at logical points, not mid-peak hours.

3. Make time for short breaks

Insert space for air line cleaning, quick inspections, or pattern touch-ups. These prevent bigger problems, especially in high-demand setups like 3-IN-1 or tight flask systems.

4. Plan around current process limits

Don’t build schedules on hopes. Base plans on current averages, not ideal conditions, and give buffer room for curveballs like delayed parts deliveries or tight resin lines.

Today’s scheduling tools give you better control. If you’re running multiple systems across bays, software helps visualize task overlap and machine pressures. That way, you can test a new schedule before rolling it out.

Tap into the experience of your operators. They’ll usually know where production drags and what tweaks could make things smoother. Bringing them in early builds trust and gets stronger support when changes go live.

Maintenance And Downtime Management

Any solid schedule should expect machines to need attention. Maintenance isn’t an interruption—it’s part of the process. From manual molding machines to high-speed automatic lines, you can’t expect systems to run at capacity without a clear plan to keep them in shape.

Downtime becomes a bigger problem when it catches you off guard. A missed check on a blowhead or stacked-up sand underneath a matchplate can bring an entire line to a halt.

The best schedules include:

– Built-in breaks for maintenance per shift or cycle

– Logs tracking what work each machine has had done

– Time stamps on completed checks to avoid repeat tasks

– Timing maintenance alongside normal job changes or restocks

This way, when a machine needs a reset or tune-up, the rest of the crew stays active. They can prep patterns, call up tooling, or check core boxes. This approach works great with dual station cold box machines, since blow and cure steps are already divided in the setup. Planning maintenance like this builds momentum on the floor instead of breaking it.

Implementing And Monitoring The New Schedule

Once you’ve built a balanced schedule, the next step is getting everyone on board. Before launch, make sure your team knows what’s shifting and why. Keep it clear. Whether it’s timing updates, machine groupings, or moved inspection points, walk through the logic behind the changes.

Be ready for feedback once it goes live. You’ll want to know early if production targets are being hit. Are mold cycles consistent on both shifts? Are matchplate and core machine load times lining up? Any unexpected build-ups on the line?

You’ll need someone checking actual output vs. schedule every day. They don’t have to be a supervisor—just someone detail-focused who can spot:

– Gaps between mold cycles

– Pattern changes going off-timing

– Mold defects linked to rushed transitions

– Slowdowns tied to missing materials

Responding to this floor data strengthens the schedule with every cycle. Say your manual crew gets delayed every morning because the pattern isn’t ready. Shift the prep backward slightly and the day runs smoother. You’re not just chasing maximum output. You’re building reliability and rhythm.

Start loose, then tighten as the team adapts. Consistency now builds speed later.

Keeping Production Schedules Flexible And Adaptive

Fixed schedules break fast when things get complicated, and in any foundry, that’s normal. From tool jams to half-cured cores, things can change quickly. Your schedule needs to leave space to breathe.

A helpful tip is adding “soft checkpoints” in the plan. These aren’t hard stops but moments for your team to take stock. If needed, they can pause, adjust, or shift workstations without causing chaos. QuickCore users might benefit from this since part swaps happen more often on vertically parted setups.

Flexibility can be built right into the shift too. Give five or ten minutes at the start for teams to reset, refill sand, or clear small jams. It’s a small time investment that pays off by avoiding stressed launches and early errors.

At one foundry using prototype core machines, shift changes used to create backlogs. Adding a 15-minute float between transitions gave crews a chance to reset fully and stay aligned. They reduced tool conflicts, made better part swaps, and saw fewer defects. Small changes compound fast when stress disappears.

Plus, flexible schedules help you adjust quickly when last-minute orders come in or high-volume days stack up. When people have room to pivot, they handle pressure better.

What It Looks Like When It All Works

Getting scheduling right isn’t about hitting perfection on Day 1. It’s about committing to keep improving the flow. As small changes stack up, everything gets easier—timing, maintenance, ordering, and morale.

Your team gets familiar with the pace. Mold quality stabilizes. Machines stay in working shape longer. Mid-shift surprises get solved faster. Your shop just works better day to day.

Make it a habit to check your schedule quarterly. Are mold cycles slipping? Is downtime creeping in? Are shift handoffs getting messy again? Ask your crew. Track time logs. Use mistakes as markers.

A dialed-in production schedule supports every other part of your shop. From better casting quality to fewer scrap parts and stronger delivery times, a well-timed floor march gives you more breathing room to grow and improve.

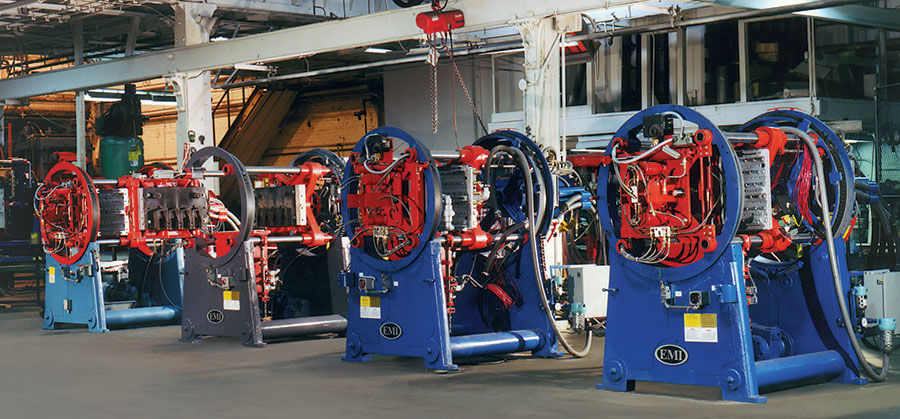

Bringing your production schedules to peak efficiency takes adjustment and attention to detail. With the right balance between planning, maintenance, and flexibility, your operations can achieve smooth flow and higher output. To explore how our equipment, like efficient molding machines, can enhance your foundry workflow, contact EMI. Let’s find the right solution to improve your process and boost productivity.