Optimizing Molding Machine Cooling Systems

Keeping molding machine cooling systems running right isn’t just about temperature. It’s about precision, cycle time, and how long your equipment lasts under steady production. The cooling system takes on a lot of responsibility during every molding cycle. If it’s even slightly out of step, the entire cast can get thrown off. That means more scrap, uneven mold surfaces, longer cooldowns, or worse, downtime.

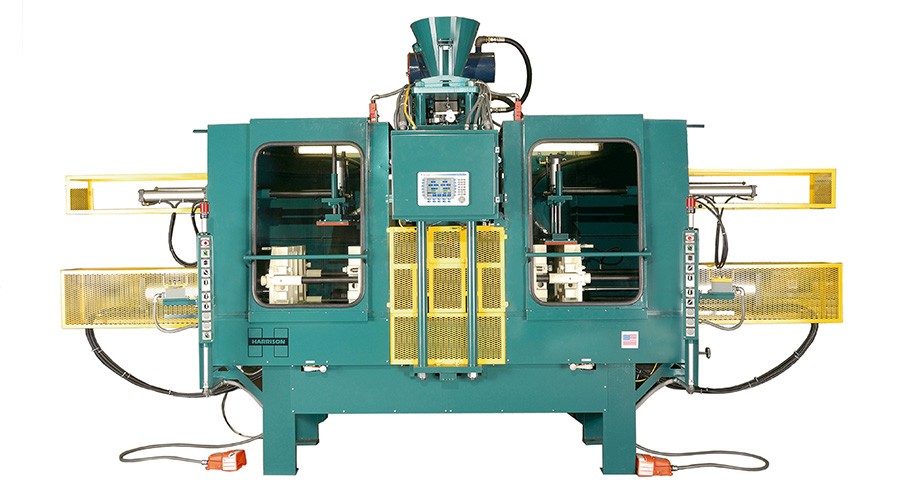

When it’s optimized, a cooling system doesn’t call attention to itself. It just works, quietly supporting the performance of everything else from sand compaction to mold separation. Whether you’re using a manual molding setup or an advanced automatic tight flask system, cooling systems help stabilize the entire process. For operations dealing with higher mold rates or long production runs, it’s easy to see how a few overlooked settings can cause bigger issues down the line.

The Role of Cooling Systems in Molding Machines

Cooling systems do more than bring the temperature down. They help control timing, manage part shrinkage, preserve tooling, and maintain mold quality. Without proper cooling, stress builds up fast in both the molds and the machine. That stress, especially over the course of a full shift, can lead to uneven castings, more rework, and added wear on internal components.

Most molding machines, whether they’re matchplate designs or automatic tight flask systems, rely on a setup that includes:

– Coolant lines running through key areas of the mold or tooling

– Temperature sensors tied to programmable logic or set timers

– Flow regulators and valves

– Chillers or water tanks that feed temperature-controlled coolant

Each component plays its part to keep things stable between cycles. If blow chambers or core boxes run too hot, for example, the mix can cure unevenly. That leads to air traps or soft sections in the mold. With high-output systems like dual station or 3-IN-1 machines, any delay in heat dissipation affects cycle time. It might be a second here or there, but that adds up fast and eats into productivity.

Even with a hybrid setup that blends manual and prototype work, keeping parts cool consistently helps reduce strip time and makes for cleaner parting lines. One common example is when hot spots form on one side of the mold while the other side stays cooler. This can make the cope or drag sections bond too tight or too loose, forcing manual corrections part after part.

Cooling isn’t just about removing heat. It’s about making the whole build process more predictable. And that predictability makes it easier to plan maintenance schedules, avoid expensive downtime, and produce higher quality molds more often.

Daily Maintenance Practices for Cooling Systems

Doing a few simple checks each day keeps the cooling system working without surprises. Every machine, manual, automatic, or somewhere in between, benefits from a steady routine. These kinds of systems don’t usually fail all at once. They slip little by little until the signs start showing up on the casting table.

Here are key daily checks operators should work into their start-of-shift routine:

- Inspect coolant flow through key zones and confirm pressure levels are consistent

- Look for leaks or disconnected hoses, especially near moving components

- Check regulator and valve positions to ensure proper system settings

- Wipe down exposed fittings to spot any slow drips or buildup

- Review current temperature settings and compare them with actual readings

- Flush standing water if the machine’s been idle overnight or over the weekend

- Make sure sensors and feedback units are free from dirt, sand, or grime

If any readings are off by even a little, it’s smart to log the difference. That way, issues can be caught early and maintenance doesn’t become a rush job later. Flow and pressure changes don’t always show up in the top line of the machine console. Operators often spot dips or spikes by feel, like valves clicking later than usual, gassing parts not staying cool, or rising mold temps between cycles.

Creating a quick checklist helps keep these steps front of mind for crews during busy shifts. Even a laminated sheet at the control station, with a dry erase pen for quick marks, is enough to maintain consistency day to day. As machines shift across production priorities, going from prototypes that run infrequently to fully automatic jobs back-to-back, the cooling system needs just a couple minutes of attention to stay ready.

Advanced Cooling Optimization Techniques

When molding machines need to run longer hours or produce more molds per hour, a basic cooling setup often isn’t enough. Upgrading specific components in the cooling system can improve consistency while reducing cycle time, which matters a lot for high-output operations.

Start with improved coolant flow. Swapping out older pumps for higher-efficiency models can reduce delays between cycles. Even small gains in flow rate make a difference, especially in dual station or 3-IN-1 molding systems that run separate molds side-by-side. Efficient flow across both sides ensures balanced cooling, which helps molds release properly and stay dimensionally accurate.

Chilled water systems are another solid option. Standard water tanks can fluctuate depending on ambient shop temperature, especially during hot months. Chillers allow coolant to remain at a set temperature regardless of surrounding conditions. These setups are common in automated tight flask systems where even minor heat creep can unbalance mold halves.

Automated temperature controls play a big role too. They allow operators to dial in heat removal based on current cycle demand instead of rough guesses. This means less wasted coolant, better part quality, and fewer manual adjustments on the floor. These systems also help reduce overcooling, which can be just as problematic since it leads to shrink defects or extended mold separation.

These upgrades don’t have to happen all at once. They can be introduced system by system, shift by shift. Whether you’re running prototypes and manual core boxes or working in high-automation setups, layering in better cooling tools makes the whole line smoother.

Troubleshooting Common Cooling System Issues

Every shop has had one of those days. Castings start sticking, mold temps shift, and nothing feels predictable. Often, the root issue sits in the cooling system. Spotting early signs of trouble helps avoid full stoppages later.

Here are common problems to watch for:

– Flow restrictions: These show up as sudden temperature spikes or long cooldown cycles. Usually caused by blocked lines, mineral buildup, or kinked hoses

– Pump failures: While pumps don’t always fail outright, they can lose power or volume over time. Look for inconsistent flow or loud whining noises during cycles

– Sensor drift: Temperature sensors can gradually shift out of calibration. If your system feels hot but shows normal reads, it’s time to verify those sensors

– Heat exchanger issues: These can underperform when sediment builds up or water circulation is off. You’ll often see uneven mold temps or one side consistently running hotter

To fix these issues, the first step is isolation. Work zone by zone. If the drag cools evenly but the cope side runs hot, you’ve already narrowed the source. Flush coolant lines, clean or replace filters, and pressure test systems once a quarter.

Quick fixes like reseating a valve or replacing a coolant line can buy time, but always keep a log. If a pump trips the same sensor three times in a week, that’s a deeper issue. Just like any other part of a molding machine, small irregularities usually snowball when ignored.

Staying Consistent for Long-Term Results

Cooling systems don’t need big changes every month, but they do need attention. Routine checks, clean water, and solid flow help keep your molding machine running smoothly across every season and shift. As demands rise from new tooling or tighter schedules, what once worked fine may start to slip.

Tracking your maintenance efforts with log sheets and regular inspections helps prevent problems before they grow. Combining quick daily inspections with long-term upgrades keeps everything more stable, especially in high-volume setups or dual station machines.

Blending newer components like temperature automation or better pumps into existing lines gives you the benefit of precision without needing a full system overhaul. When cooling systems hold steady, molds stay clearer, parts need less work post-pour, and production stays on schedule.

Whether you’re scaling your operation or just keeping things steady, clean coolant and smart timing make a stronger foundation for every casting.

Ensure your production remains efficient and precise by learning more about our range of molding machines. At EMI, we understand the demands of the metal casting industry and offer solutions that help you maintain quality and consistency. By integrating these machines into your operations, you can minimize downtime and optimize performance. Contact us today to discuss how our innovative equipment can meet your specific needs and take your operations to the next level.