How To Handle Molding Machine Jamming Issues

When a molding machine stops feeding or closes mid-cycle, it doesn’t just pause production — it disrupts everything around it. From core box alignment to sand flow, a jammed molding system causes costly downtime, uneven cycles, and sometimes even tool damage. Whether you’re running a manual matchplate setup or an automatic tight flask system, keeping that equipment moving smoothly is the backbone of staying on schedule.

Jamming is one of those headaches that most foundries have run into at some point. Sometimes it’s a simple material blockage. Other times, it’s worn parts that finally gave out or a deeper mechanical issue that’s crept in over time. Knowing what to look for and how to act quickly can be the difference between a five-minute pause and a full shift lost to repairs. Let’s go over common causes and how to stay ahead of the problem before it stops production.

Identifying Common Causes Of Jamming

Molding machines are built for tough, repetitive jobs, but like any equipment, they’re going to wear out without the right care. Most jams don’t just happen out of nowhere. They build up over time because of missed checks, worn parts, or other operational stress.

These are the common causes of jamming found in both manual and automatic molding machines:

– Material buildup: Sand and debris leftover between cycles often harden in tight clearances. That buildup can eventually block movement or throw off alignment.

– Worn or damaged components: Pattern plates, pins, and guides take constant wear. If they warp, crack, or start binding, jam points form anywhere contact is made.

– Mechanical failures: Faulty pneumatic or hydraulic systems reduce alignment accuracy and smooth motion. Seals wear out and pressures fall off, making jams more common.

– Poor pattern alignment: Misalignment happens with machines like Osborn Matchplate or automatic flask systems. Even a slight shift can cause parts to clash mid-cycle.

– Inconsistent sand flow: High-output molders depend on steady sand delivery. If the material sticks, clumps, or starves a cavity, the cycle stalls or fails completely.

Jam-prone areas tend to include the draw zone, sand gate, return stroke unit, and ejector systems. Any spot that moves under power, especially under repeated heat and pressure, becomes a potential sticking point — especially if routine cleaning slips behind.

Automatic machines have more points of failure across their electronics, sensors, and air systems. Manual systems depend more on tight mechanical action. Both machine types, though different, require the same layered attention to avoid shutting down mid-cycle.

Preventive Maintenance Practices

Jams are nearly always avoidable when the routine upkeep is there. Daily and weekly checks might take time, but they protect your equipment from bigger problems. Operators should build these habits into the shift so nothing slips through.

Here are some basics that make a big difference in long-term molding performance.

Daily Checks

- Clean off sand and debris from pattern plates, clamps, and guide rails. Even small dry spots can lead to buildup on the next cycle.

- Check for wear, bending, or misalignment in key components like the pattern draw plate.

- Make sure hydraulic or pneumatic pressures are on target for the workload.

- Inspect the path and condition of the sand feed line to prevent clogs.

Weekly Tasks

– Lubricate springs, cams, guide rods, and ejectors depending on the machine’s layout.

– Look at pivot points, pins, and joints. Machines running multi-shift days will wear those points down faster.

– Check pressure hoses, air lines, and electrical feeds, especially around moving sections.

– Run a quick test on emergency and reset functions to confirm the system can halt or recover safely.

One spot that can’t be overlooked is the sand delivery system. If it’s pulsing or feeding too slowly, your mold won’t fill right. That often leads to partially formed cores or full jams as plates try to move before the cavity is loaded. Older systems in particular need close inspection of the blow head, seals, and coupling points.

Watch your pattern plate spacing. If it’s drawing unevenly or starting to stick, that’s another red flag. It affects both part quality and movement smoothness — and eventually feeds into full-system resistance if left unchecked.

A regular maintenance rhythm helps teams spot weak spots and schedule repairs before a shutdown happens. Jams strain machines. The more they lock up, the faster other components begin to fail too. Maintenance resets that clock.

Troubleshooting Steps For Jamming Issues

If the machine freezes and won’t cycle, powering through it is the worst idea. That can snap pins, damage guides, or break the tooling altogether. Stopping and working through a basic diagnostic process solves most issues without additional damage.

Below is a step-by-step guide teams can follow on the floor.

- Pause the cycle and shut down power: Fully lock out and bleed off stored energy. Don’t just rely on touchscreen resets.

- Inspect contact zones: Look for obstructions around clamping areas, draw mechanisms, and sand ports.

- Use manual override: Try easing motion through the bind. If it won’t budge, pinpoint resistance points before applying more pressure.

- Check hydraulic or air systems: Look for pressure drops, slow cylinder speed, valve failure, or obvious leaks.

- Check pattern alignment: Any misalignment in matchplate or flask equipment can cause jammed plates or twisted frames.

- Run a test cycle empty: If repairs are made, dry-run the machine before loading up again to test cycle timing and clearances.

If your team sees repeated jams at the same point, keep a log. Location-based jamming often points to wear in specific mechanisms like ejection or venting. That kind of pattern helps isolate bigger root causes — sometimes mechanical, sometimes sensor or timing related on automatic molding solutions.

Don’t rush a reset during mid-shift. Stopping to clean out a vent valve or check the core draw on systems like QuickCore can prevent hours of unnecessary downtime just a few cycles later.

When You Need Outside Support

If the same jam keeps coming back even after cleaning, lubing, and checking alignments, the issue likely runs deeper than worn surfaces. Knowing when to loop in outside help is key to protecting your line from major downtime.

It’s time to call in support if you’re seeing:

– Jams during the same operation every time

– Odd noises or movement during ejection or core draw

– Fast alignment drift even after machine reset

– No or uneven pressure from pneumatic or hydraulic systems with no clear leaks

– Inconsistent jamming that happens only under full load conditions

Regular external inspections are a smart move. Operations with dual station units, QuickCore machines, or mixed manual-automatic lines often need a broader set of inspection methods. A short visit from a trained technician can expose issues that internal checks may miss, especially inside older systems or where operator rotation is frequent.

Delaying professional service to hold onto production time can backfire. A stubborn bind might start with one jam and turn into a cracked draw mechanism or frame damage within a few cycles. If things feel abnormal — don’t guess. Bring in someone who knows what to check.

Avoiding Downtime One Fix at a Time

Foundry productivity hinges on every cycle. When a molding machine jams, it doesn’t just eat up time. It shifts the entire schedule, reroutes labor, and risks part quality.

The best fix is usually the first one. Keep sand flow balanced, plates aligned, and moving parts clean. Don’t skip checks, and don’t keep delaying repairs. Most binding issues start small and show signs before machines freeze up. Recognize the signs early, and treat them like part of the cycle.

Matchplate molding machines, automatic flask systems, core machines like QuickCore or 3-IN-1 setups — each type has its quirks. Familiarity with how your machines behave when healthy is the best tool in fighting back against jams.

Whether your molding equipment is brand new or has run thousands of hours, the right combination of maintenance and professional support will keep it moving. And when it does, so does your production. Stay on top of it, stay ahead of the jams, and your lines will keep running.

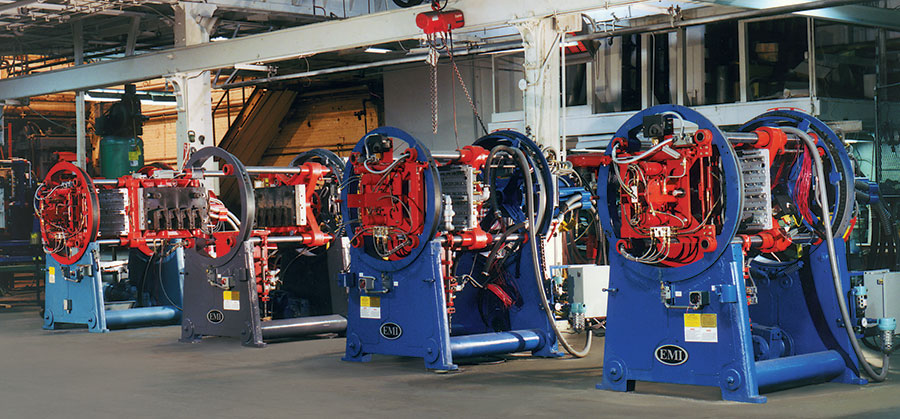

Keeping your operations efficient and trouble-free is key to staying on track with production goals. If you’re often dealing with equipment downtime, it may be time to upgrade or replace outdated systems. See how EMI can support your success with reliable molding machines designed to help your line run smoother with less interruption.