How To Ensure Core Machine Compatibility With Sand Types

Matching the right sand with the right core machine isn’t just about squeezing better performance out of your setup. It’s about protecting your equipment, maintaining mold quality, and keeping production consistent without throwing off your timelines. Even a small mismatch between machine specs and sand composition can cause friction, leading to system inefficiencies, increased scrap, or unexpected downtime.

Different machines respond to sand types in different ways. Some need fine-grain sand for tight detail. Others handle coarser blends that speed up the cycle. Without understanding how machine design interacts with sand chemistry and texture, teams might end up working against their equipment. The goal is simple: avoid problems upfront by making smart compatibility decisions early.

Understanding Core Machine Types and Sand Compatibility

Foundries vary in how they operate, but there’s a wide variety of core machines to support any casting style or workflow. Each machine is built to perform at its best under certain conditions, including the type and quality of sand used.

Core machines include:

– Cold Box Core Machines: These use gas-hardened binders and work best with sands that balance flowability and strength.

– High Production Core Machines: Built for large production runs. These machines do well with consistent sand batches and steady binder systems.

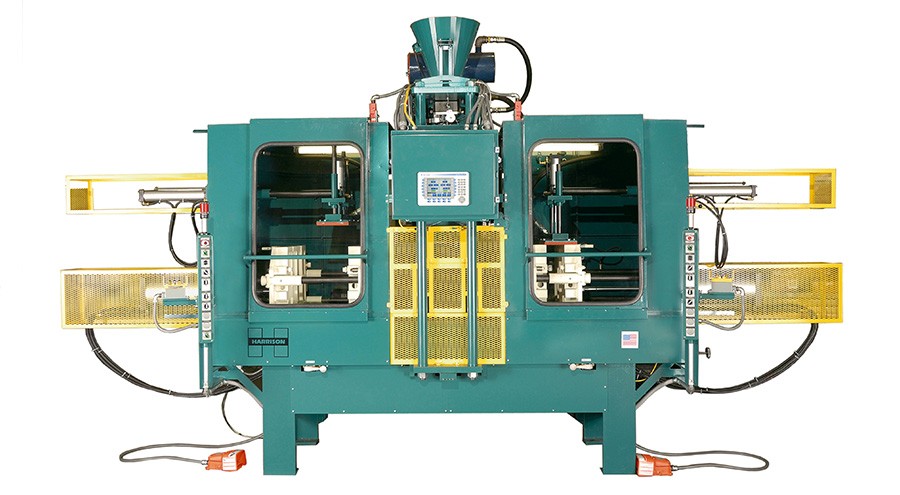

– Dual Station Core Machines: Their two-station layout keeps production moving. Sands that set faster are often used to match the cycle speed.

– QuickCore Machines: With vertical parting, these are well-suited for detailed components. Finer sand helps reduce surface flaws.

– 3-IN-1 Core Machines: These offer flexibility but can be disrupted by sudden changes in sand properties.

– Prototype and Manual Machines: These are more reactive to sand inconsistencies. Small differences in texture or moisture can impact compaction and stripping.

When it comes to sand, choices vary widely. Finer grains give excellent surface finish but may clog tubes. Rounder grains help with compaction but reduce fine detail. Shell sands behave differently than coated ones under pressure. Binder compatibility with gassing equipment must also be considered. A sticky sand blend, for example, may require more purging and clog up crucial pathways.

Problems often arise when switching suppliers or altering binder systems without testing for flow, compaction, or curing differences. One example is a facility using a high production cold box machine that switched to a cheaper sand blend. The slower flow led to underfilled core boxes and incomplete parting lines, increasing daily scrap.

Compatibility covers several details: airflow, binder activation, moisture content, cavity shape, and more. The better each machine pairs with a specific sand blend, the fewer slowdowns and the more consistent the output.

Best Practices for Matching Core Machines with Sand Types

Pairing the right machine and sand type takes planning. Here are a few steps to make sure they work together:

1. Review machine sizing and airflow specs before using any new sand blend.

Check the manual or consult with a technician to determine what grain type and binder formulas your setup supports.

2. Begin with a small trial run for each new sand.

Form a few test cores and inspect for problems like poor surface quality, blowouts, or uneven compaction.

3. Track any performance shifts when sand or binders are changed.

Note changes to cycle times, air pressure usage, and stripping completion.

4. Check core boxes and tool surfaces after early runs.

Fine dust buildup or residue may be a sign of binder issues or poor curing.

5. Monitor moisture and temperature consistently.

Since each blend holds moisture differently, binder performance can change with seasonal conditions or varied storage conditions.

These checks help highlight weak spots before they impact your daily schedule. Without them, crews could spend too much time fixing issues that show up unexpectedly from a small spec change. Regular maintenance and performance logging also help track how small updates impact core quality. Often, changing binders might mean adjusting heat settings or vent timing to keep results on track.

Common Issues and Practical Fixes

When core machines and sand batches don’t align, the warning signs start fast. Lagging cycle times, poor-quality cores, and inconsistent mold fill are just a few of the problems you might see. Many of these result from binder reactions, poor grain spec, or machine settings that weren’t adjusted for the new materials.

Issues to watch for include:

– Cores collapsing during stripping

– Poor parting surface detail

– Resin or catalyst sitting in hoses too long

– Unexpected runtime increases

– Uneven wear on blow tubes, vents, and box seals

One case involved a Dual Station Cold Box Core Machine facing performance drops. Operators noticed compaction problems that didn’t match machine logs. Eventually, an investigation showed the sand was absorbing more ambient humidity, affecting flow and reaction time. Even though basic checks showed nothing unusual, skilled operators picked up subtle changes during cleaning. Adding dry storage and tweaking blow timing fixed the issue completely.

Operators make a big difference here. The most experienced team members often learn to recognize early warning signs like flow shifts or resin smells that aren’t in spec. Training employees to understand sand traits and how they react during curing or compaction adds a safety net around unexpected changes.

Tooling inspections also matter. Machines strain more when sand doesn’t release well, and that strain adds wear in hard-to-see areas. It helps to update your equipment checklist anytime you switch formulas or update supplier specs. It’s better to adjust early than face chronic downtime down the road.

How Technology Supports Sand-Machine Compatibility

Smart tools now help detect compatibility risks early. These aren’t a fix-all, but they give teams more data to react faster and avoid guesswork. When used properly, even small gains can smooth out entire production shifts.

These tools include:

– Temperature and pressure sensors that alert on real-time changes

– Maintenance software that tracks performance shifts over time

– Mold-fill simulations that show sand behavior in the machine cavity

– Resin dosing systems that control formula mix and feed rate

One team testing new sand mixes in a prototype 3-IN-1 Core Machine saw random curing delays. At first, no physical problem showed up. But system pressure readings revealed prolonged recovery at a few points per run. By tracking cycle data, they discovered the new sand blend included a pitch that didn’t vent cleanly. That simple swap created sticking points in tooling, which caused time loss between pours.

Technology shows its value in shift handoffs as well. Teams run more smoothly when they can check logs and monitor results in real time. Everyone sees what’s changed and why. Over time, this leads to fewer run interruptions and stronger shift-to-shift consistency.

Digital tools are especially helpful when working with systems like Osborn Matchplate Molding Machines or Savelli Tight Flask Molding Solutions, where repeatability and material specs play a larger role.

Keeping Machines and Sand in Sync All Year

Long-term results come from steady planning and consistent follow-through. It’s not just about pairing a good blend with the right machine. It’s about keeping the whole system tuned as conditions shift over time.

Schedule frequent sand checks. Recalibrate your settings when binder or resin formulas change. Monitor for small process drifts that may creep in after a few weeks of similar runs. These steps help you avoid sudden performance dips that are hard to trace.

Stay in contact with your sand and binder suppliers, too. Open conversations keep you informed on changes before they affect your machines. Combined with trained operators and strong recordkeeping, you’re more likely to catch problems while they’re still easy to fix.

Humidity levels, storage changes, or a new core box design may all impact how well your current setup runs. Being proactive with operator checklists and monitoring tools makes it easier to hit the spec on each job. When problems do show up, you’ll be ready to adjust quickly and stay productive.

The more aligned your machine setup is with your sand mix, the better your castings will come out—and the fewer surprises you’ll deal with across shifts and seasons.

Achieving seamless operation and optimal production in your foundry involves a keen understanding of how different materials interact. By ensuring that your equipment and materials align perfectly, you can avoid disruptions and maintain high-quality output. For support on choosing the right solutions for your core machines, EMI is ready to assist. Let us help you streamline your operations and keep your production on track.