Core Machine Temperature Control Problems

Maintaining proper temperature control in core machines plays a big role in keeping casting quality consistent. When temperatures swing too far in either direction, defects are more likely to show up. Cold shut, poor surface finish, gas-related flaws all can be traced back to thermal inconsistencies. Most machine operators know this, but the headaches begin when they can’t seem to figure out what exactly is causing the temperature shifts.

Fall is a good time to reassess these issues. As the cooler weather arrives, some shops struggle with machine performance dropping off due to colder ambient conditions, while others work through leftover summer heat that throws off internal temperatures altogether. No matter the season, overlooking how heat and airflow behave inside your equipment can lead to avoidable problems down the line. Let’s take a closer look at why this happens and how to stay ahead of it.

Understanding Temperature Control In Core Machines

Core machines rely on stable internal temperatures to produce solid, defect-free cores. Within the cold box process especially, an even curing temperature is needed to react properly with chemical binders. If that temperature runs too cold or climbs too high, the core may not cure as intended. This can cause dimensional problems or even structural failure when the core is set into place.

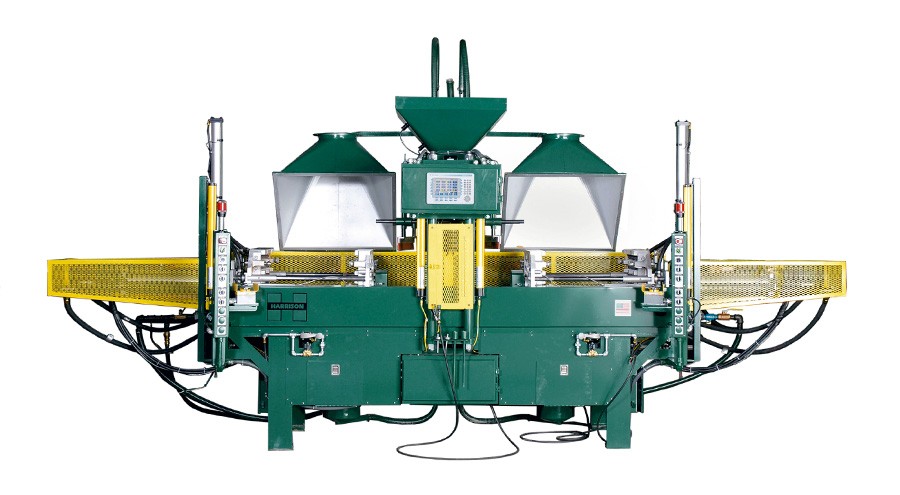

Beyond curing, temperature affects the entire setup. The tools and components inside the machine operate within a certain heat range. Whether you’re running a dual station system or a quick-change setup like QuickCore, each part of the machine needs the right balance of temperature and airflow. Operators should also keep in mind that newer high production models tend to maintain heat better than older manual setups, which means older equipment may require more active monitoring.

Here’s how temperature affects core quality at different points in the process:

– Chemical reaction: If the temperature isn’t right, the chemical binder won’t react thoroughly or properly

– Curing time: Lower temperatures take longer to cure, while excessive heat can lead to premature reaction or core cracking

– Core strength: Inconsistencies in temperature lead to weak spots or uneven density across the core

– Dimensional accuracy: Uneven heat can cause expansion differences leading to out-of-spec results

When you fully understand how these systems manage temperature, from airflow design to material contact time, it becomes easier to spot the warning signs and make adjustments before bad parts reach the mold zone.

Common Temperature Control Problems And Their Causes

Frequent challenges arise when trying to pinpoint why temperature issues keep popping up in core machines. Some problems are obvious, while others require deeper inspection into how the machine is set up or maintained over time.

Here are several common temperature control problems and what’s usually behind them:

1. Irregular cure rates: Often caused by fluctuating ambient shop temperatures or inconsistent airflow inside the machine

2. Overheating components: This can happen when cooling systems are blocked or filters go unchanged too long, making it hard for parts to regulate their heat

3. Cold corebox surface: If the corebox isn’t preheated or held at the right temperature, cores may crack or not release cleanly

4. Control system lag: Temperature probes or sensors that are slow to respond or poorly calibrated will send delayed signals, affecting heating and cooling cycles

5. Material storage temperature: If binders or sands are stored in an area that’s too hot or too cold, they’ll introduce temperature variance before they’re even in the machine

Letting even one of these problems slide can create a ripple effect through the entire operation. A poor cure is more than just a time setback. It leads to rework, wasted materials, and higher repair costs over time. Understanding the source of these changes allows teams to adapt quicker and develop more reliable routines. The next step is knowing which products need upgrades and which areas can be adjusted through simple process changes.

Solutions For Effective Temperature Management In Core Machines

Once temperature-related problems are identified, the next step is making reliable adjustments to improve control. Effective temperature management often comes down to a few steady habits paired with proven equipment design. Good airflow systems, accurate sensors, and consistent material handling routines all work together to create balance inside both the core box and the machine itself.

Different types of equipment have their own temperature behavior. A high production core machine, for example, handles heat loads differently than a manual or prototype system. It’s important to understand how each model distributes air, retains heat, and reacts to room temperature shifts. Vertical and horizontal parted cold box machines, dual station setups, and 3-IN-1 systems each have their strengths, but they still rely on proper temperature input and regulation.

Here are a few steps teams can take to improve core machine temperature performance:

– Upgrade sensors or calibrate existing ones to improve accuracy and feedback response

– Install or improve localized heating systems around core boxes and chemical feed lines

– Seal areas that allow ambient air to leak into the machine space, especially during fall and winter

– Schedule regular cleaning for exhaust fans and intakes that may be clogged with material dust

– Keep sand and binder materials in temperature-controlled zones to reduce input variation

Even well-calibrated systems can break down over time if feedback loops aren’t maintained. An air valve that leaks or a temperature probe that hasn’t been checked in six months can throw off entire runs of cores before anyone sees a red flag. An operator we worked with found out the hard way when sudden weather shifts caused his dual station core machine to under-cure every other core. Turned out the problem wasn’t with the machine itself but with a small blocked air duct overlooked during routine checks.

Best Practices For Monitoring And Maintenance

Strong temperature control depends on regular visibility into system health. Too often, monitoring gets pushed aside for speed, but that leads to longer outages and poor casting quality later. Building a playbook of daily, weekly, and monthly checks helps prevent breakdowns and keeps scrap rates low.

Here’s one simple routine that works well for many shops:

Daily:

– Check probe and sensor readouts against known temperature baselines

– Inspect vent and duct openings for dust or obstructions

– Confirm preheat cycles are reaching target temperatures before starting production

Weekly:

– Run airflow tests across different machine chambers, especially important when using dual stations

– Cycle backup heaters and cooling units to keep them in operational condition

– Compare post-cure core strength against temperature logs

Monthly:

– Clean fans, filters, and thermal insulation layers

– Validate calibration on sensors and record output accuracy

– Review chemical and sand storage areas to ensure materials are consistent

These regular checks stack up over time to support smoother, more predictable line runs. With the colder months approaching, it’s also smart to increase frequency when new seasonal problems start to show up. Machines that ran fine during the summer might develop issues when cold shop air mixes with the thermal flow inside your system. Stay flexible, but stay consistent.

Keeping Temperatures Steady for Better Results

Maintaining proper temperature inside your core machines affects more than just individual cores. It plays a role in safety, productivity, and part quality across the whole shop. Inconsistent heat can slow down cure cycles or weaken structural bonding, making it harder to meet expectations on final castings.

A reliable temperature control plan allows each machine, from a single-station prototype setup to large automatic systems, to stay on track no matter what material you’re using or how big the run size is. By focusing on variables like airflow, ambient temperature effects, and material storage habits, foundry teams can lock in better repeatability from day to day.

Whether you’re working with cold box systems or advanced molding setups, building strong temperature habits leads to fewer surprises and better castings. It’s one of those behind-the-scenes factors that’s easy to overlook until it’s too late. But with the right steps in place, it becomes one of the easiest things to control.

Regular maintenance and a solid understanding of your core machines can make a big difference in preventing temperature-related issues. For industries looking to refine their processes and improve output, learning more about advanced core machines could be the next logical step. EMI provides solutions built for both ferrous and non-ferrous foundries, helping teams increase consistency and lower scrap rates across the board.