Training New Operators for Cold Box Machine Safety

Cold box machines bring a lot of moving parts, both literally and in how they function during a shift. For new operators stepping into the shop, that mix of precision, power, and timing can feel overwhelming fast. The job requires more than just instructions or a printed manual. It takes hands-on learning, awareness of seasonal shifts, and a clear understanding of how the equipment should behave. Getting someone comfortable with our machines does not happen by chance. Solid safety habits, a basic grasp of how core machines operate, and real-world guidance help operators spot and respond to shifts before they cause damage or delays. Each task builds on the one before it, and when training starts that way, everyone wins.

Understanding the Machine Before Operation

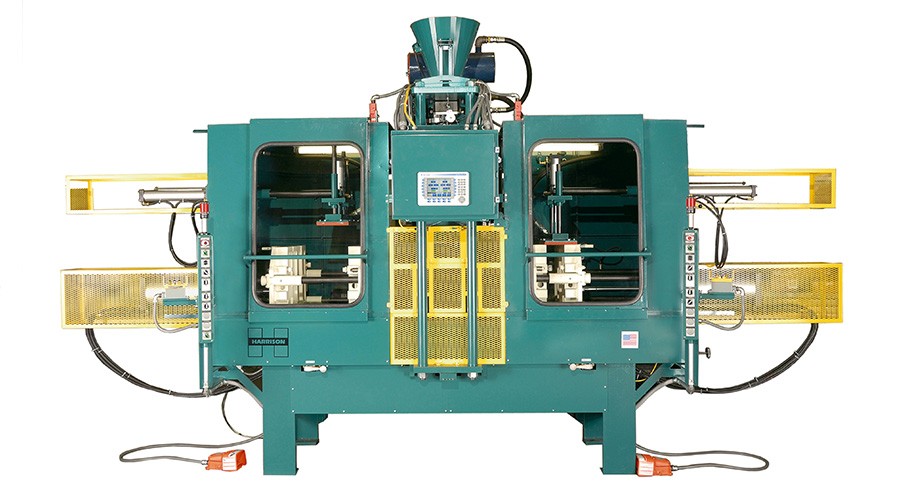

Before anyone touches the controls, they need to know what each part of the system does and why it matters. Cold box core machines play a key role in our daily flow, so learning their function is where we begin.

- New operators should walk through the layout of a core machine, from sand delivery points and resin feed to the blow plate and core box.

- They also need to know how purging works and where to check for vent paths. Little things like a misplaced hose or clogged vent can cause bigger problems later.

- Before startup, we look at pre-run checks. That means verifying air pressure, inspecting the box alignment, and making sure sand levels are steady and dry. If it’s the end of winter, that sand might be sluggish or holding cold longer than expected, which affects everything downstream.

We do not throw someone into a shift cold. First, we walk them through what a good start looks like so they are not just responding to mistakes after they happen.

Teaching Safe Start-Up and Shutdown Procedures

A good start begins long before the start button gets pushed. In colder weeks like late February, air behavior and resin cure times shift without much warning. That is why step-by-step procedures matter.

- On startup, we give the machine time to reach a steady temperature. This helps keep the sand flow more predictable and stabilizes pressure within the system.

- If we skip warm-up, resin could bond too fast or sand might jam before the core even forms. Cold temperatures do not just affect comfort, they drift into machine response.

- At the end of a run, shutdown is just as important. Bleeding off air pressure, clearing sand from paths, and noting any delays during the shift gives the next operator a smoother entry point.

These are not just habits, they are part of building muscle memory that drives safer, more consistent production.

Operator Awareness During Production

Once the run begins, operators move into a different role. They are not just involved in setup, they become the machine’s closest observer.

- A big part of the job is noticing when things do not feel right. It might be a pressure adjustment, slow sand flow, or cores coming out with uneven lines.

- Seasonal changes show up here too. A cold snap in the shop can make resin slow to cure, while leftover winter humidity drops might tighten airflow and clog jets.

- When something goes off mid-shift, waiting too long to address it costs both time and product. Operators should know how to pause, look under the cover, and call in support before the line backs up.

That attention only gets sharper with practice, but we can train it by encouraging slow, focused observation early on.

Reinforcing Proper PPE and Operator Positioning

Safety gear and personal spacing often get skipped in a rush, but we slow things down for a reason. Starting with good habits makes sure operators do not learn the hard way.

- PPE is not just gloves and glasses, it should include hearing protection and long sleeves when near blow stations. We show new operators what each setup requires and why skipping small steps is not smart.

- Positioning around the machine matters too. Cold box cores can involve heat, pressure, and shifting boxes that do not look dangerous until they are.

- Operators working near dual stations or shared lines need to know where to stand, when to shift, and what signs to watch for when others are running machines nearby.

When we prep people to move confidently and mindfully, safety just becomes part of how they work.

Keeping Quality and Safety Consistent Over Time

A good training session is not a one-time thing. We keep skills sharp by feeding back lessons from recent runs and promoting shared problem-solving between shifts.

- Peer shadowing builds comfort. Watching a more experienced operator walk through daily checks helps new workers see how habits work under pressure.

- Keeping written or digital logs during shifts lets us track machine quirks across weeks. If something odd shows up in late February, patterns from past seasons might already hold the answer.

- Operators also collaborate with leads and maintenance. When they report changes quickly, we get to small repairs before they fester.

Consistency comes from the small stuff. Logs, questions, quick check-ins, these things keep the line working even when the shop throws a curveball.

Building Confident Operators Who Can Spot Trouble Early

Training runs deeper than instruction. We want operators who feel confident when a pattern breaks or a machine begins sending a bad signal.

- Good training gives workers space to ask questions and time to make mistakes in a safe zone before the stakes are high.

- Instead of just reacting, seasoned operators learn to look ahead. They know how flow should feel, how the core should cure, and what a healthy cycle looks like.

- With practice, that becomes second nature. Cores mold cleaner, shifts move faster, and the shop spends less time chasing preventable issues.

Cold box training is not just about parts and buttons. It is about building real awareness that keeps machines, people, and product moving together.

At EMI, training our operators goes beyond safety and basic controls, it is about making sure they understand how tools like our core machines perform under real shop conditions. By recognizing how factors such as cold starts, resin behavior, and sand flow can change daily, your team can take the guesswork out of production. We believe nothing should be left to chance, in operations or training. Reach out to discuss how we can help you build more confident crews and achieve greater consistency in your operation.