Power Supply Problems in Automatic Molding Systems

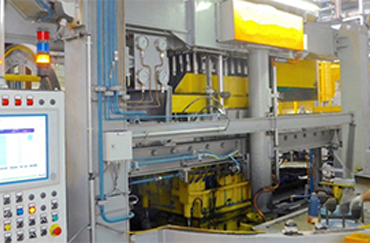

Automatic molding machines have changed how foundries operate, offering better speed, consistency, and overall quality. These systems help reduce manual labor and increase daily output. But when something as basic as the power supply fails, the rest of the setup can’t function properly. Even one electrical misstep can interrupt operations, cut into deadlines, or damage expensive components.

Power problems are not always obvious. They might first show up in small ways, like poor mold packing or flickering display screens. Ignoring these signs can shorten the life of equipment and lead to unplanned downtime. That’s why understanding and managing electrical stability in molding systems is key to keeping production reliable and on track.

Common Power Supply Issues in Automatic Molding Machines

A solid power supply supports everything from the main machine control units to motors and mold transport drives. If the incoming power isn’t consistent or strong enough, the rest of the system struggles to keep up. Here are a few of the most common power-related issues that automatic molding machines face:

– Voltage Fluctuations: Spikes or drops in voltage can impact sensitive components like sensors and programmable logic controllers (PLCs). These changes may not cause immediate failure but can create damage over time.

– Phase Imbalance: Most molding systems run on three-phase power. If one or more phases don’t carry equal loads, motors can overheat or sustain uneven wear during each cycle.

– Poor Grounding: Grounding errors can cause dangerous electrical interference and increased wear on contactors or relays. Poor grounding is both a performance issue and a safety concern.

– Loose Wiring: Terminals in high-use areas or breaker panels can become loose, especially after repeated heat cycles. A single loose wire might result in system resets or blown fuses.

– Damaged Cables: Wear and tear from vibrations, bending, or environmental exposure can harm power cables, creating resistance points and leading to localized heating, which degrades performance further.

Workloads are often running full tilt in foundry settings, and any drop in electrical quality can snowball into mechanical issues. All it takes is inconsistent power to trip a machine offline, ruin a mold cycle, or confuse the automated system controls.

Impact of Power Supply Problems on Molding Machines

Ignoring power problems won’t make them go away. Over time, even small electrical inconsistencies put extra stress on the systems designed to keep production moving. These are just a few areas where damage can occur:

– Motor Failures: AC motor systems are sensitive to poor voltage balance. If one phase lags or overdraws, high temperatures build up fast. That can burn insulation, seize bearings, or cause breakdowns unexpectedly.

– PLC and HMI Errors: PLCs and Human Machine Interfaces rely on uninterrupted voltage levels to relay signals and store data. Power dips can result in scrambled readings or lost automation routines.

– Mold Quality: Systems relying on set mold pressure or shot speeds may underperform if power drops slightly, even for a short time. That leads to air pockets, incomplete mold fills, and inconsistent results.

– Production Delays: Misfired cycles or blown fuses create delays. If these become routine, it affects job scheduling and team workflow.

– Higher Repair Costs: When parts fail due to power-related stress, replacements take time and money—especially if you must rush an order or call in specialized support.

Overloading equipment without maintaining the power supply can create wear patterns that are hard to fix later. Being aware of these patterns helps foundries act sooner and avoid emergencies.

Diagnosing Power Supply Problems

Finding the source of electrical trouble should be the first step before repairs begin. Technicians benefit from starting with the observed symptoms and then backing up through the system’s components.

For example, ask when and how the system shows signs of a problem. Does it lag during startup? Do alarms flash mid-cycle, or does the panel shut down suddenly?

Here are some ways to pinpoint those problems:

– Use thermal imaging tools to detect hot spots in panels, wiring junctions, or motor terminals.

– Use a digital multimeter to test for voltage imbalance across all phases.

– Use a clamp meter to check load draw from the main service lines feeding the machine.

– Check diagnostic logs inside your PLCs or HMIs. They often timestamp errors linked to undervoltage or overload conditions.

A full diagnosis may call for checking both upstream and downstream parts of the system. Sometimes the problem doesn’t come directly from the machine. It could be tied to other equipment drawing power from the same service panel or from aging transformers that lose efficiency under high demand.

A thorough wiring inspection is another must-do. Components like contactors, overload resisters, or isolation switches face regular wear and should be included in scheduled reviews. Those operating high-output machines like a Savelli tight flask system or automatic matchplate equipment may see wear rates climb faster due to continuous production.

Solutions and Best Practices That Work Long-Term

Once a power supply issue is identified, the repairs need to solve more than just the immediate fault. Addressing root causes and adding permanent safeguards makes recurrence less likely.

Below are long-term solutions and approaches that work well across molding machine setups:

- Install dedicated surge protection devices at control panels.

- Replace or strengthen grounding paths to ensure error-free current flow.

- Inspect cable insulation and connectors for damage, corrosion, or overheating marks.

- Measure all three-phase lines for balance and set a schedule for regular load testing.

- Prioritize preemptive part swaps for components like contactors or PLC power modules.

- Avoid crowding high-capacity equipment with accessory tools using shared power supplies.

Maintaining a data history from voltage monitoring devices also helps. Spotting a repeated trend like voltage drop during high-load periods gives early warning that a larger issue may be near, such as transformer overloads or undersized circuits.

By tracking these patterns, foundries can take action on issues before they grow into outages or equipment failures. Spending time on prevention today avoids unplanned downtime tomorrow.

How to Keep Operations Running Smoothly

Effective maintenance doesn’t just mean fixing problems when they happen. Through routine upkeep, electrical issues can be spotted much earlier—and sometimes completely prevented.

Create a maintenance plan that includes:

– Weekly inspections of wiring, terminals, and fuses

– Monthly torque checks of screw-type terminals inside any major control system

– Infrared scanning every six months to check for heat points inside power and breaker panels

– Annual transformer and feeder load analysis to verify capacity limits

– Regular cleaning of control panels and movement of dust-sensitive components

Operator training is also part of a preventive strategy. Experienced workers may recognize buzzing sounds, hot smells, or mid-cycle slowness as small warnings. Encouraging quick reporting of these observations helps maintenance staff take early steps. Even a slight drop in packing pressure or motor torque during an automatic molding cycle could signal something deeper happening with the incoming power.

Staying Ahead of Power Problems

Any foundry that counts on consistent production knows that machine uptime matters. An automatic molding system is only as reliable as the power fed into it. As equipment continues to automate, the margin for error gets smaller.

Instead of waiting for a breakdown or blown relay to stop a shift, the stronger plan is to understand the electrical demands of your molding systems and act early when signs show up. There’s often something to fix before failing parts give out entirely—if you tune in to the right indicators.

Small shifts in cycle time, overheating motors, unexpected alarms, or even slightly inconsistent mold shapes could point to the same thing: unstable incoming power.

Keeping your machines running strong starts with keeping the power flowing exactly the way it should. By checking carefully, maintaining deliberately, and responding quickly, foundries can rely on less downtime and greater long-term output from every molding machine on the floor.

For those looking to keep their operations running smoothly, it’s important to catch electrical issues before they lead to bigger problems. EMI offers a variety of reliable solutions, including molding machines, built to handle the demands of modern foundries. With a focus on routine maintenance and power stability, your team can count on greater uptime and longer equipment life.