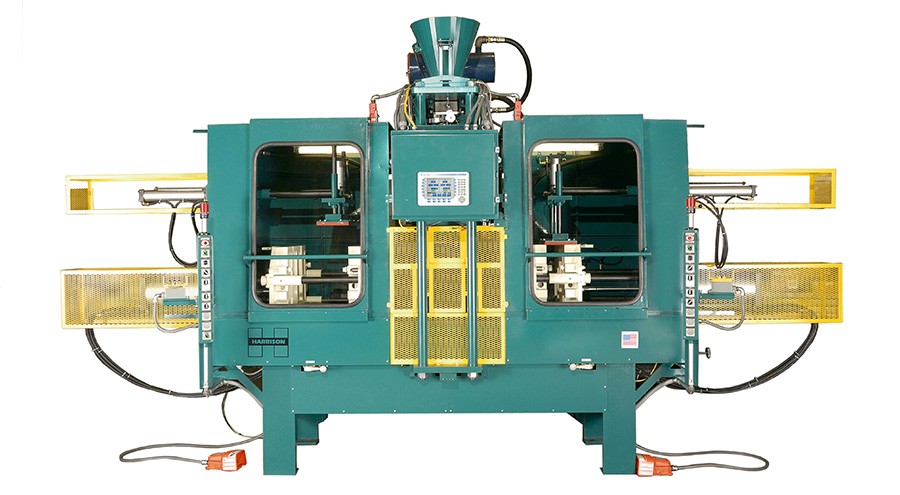

How to Set Up Dual Station Core Machines for Winter Runs

Running core machines efficiently in cold conditions starts with how we set them up. Dual station core machines carry more moving parts and control systems than other layouts, so getting them prepped for steady winter performance matters. January and February bring colder starting temps, longer warmup windows, and challenges across air and fluid systems.

The good news is that it does not take an overhaul to run clean through the colder weeks. With a better feel for how cold affects air flow, motion timing, housing temperatures, and startup behavior, we can make small changes that help everything move on schedule. By seeing how these conditions interact with the machines, we get ahead of problems before they show up on the floor.

Understanding How Cold Affects Machine Functions

A typical winter start-up does not just take longer, it also hits different pressure points in how dual station systems function. Cold compresses more than shop temp. It reaches into the pathways and fine controls that keep timing steady.

- Pneumatics stiffen when dry air carries moisture that freezes in regulators or valves

- Hydraulic systems lag as oil thickens and slows return movement

- Servo and motion controls skip or reset when cycle speeds drop too far below norm

- Material feed may slow if resin lines or blower temps fall short of cure specs

Add in temperature swings across the day, and even cycle-to-cycle consistency suffers. Warm gear from one shift might cool too fast before the next, breaking output rhythm. These small disruptions stack up quickly if conditions are not adjusted to how core machines actually behave in winter.

Cold winter conditions sneak into every system, not just the obvious ones. Even with a heated shop, certain corners may remain colder, which leads to slow response on valves or delayed startup. Recognizing which components are most exposed to these drops is key to bringing your machines online faster with fewer errors. Over time, this attention close to the floor can help save parts and avoid wasted time diagnosing problems that really stem from room temperature.

Heat Management Around Core Machine Operations

One change that pays off fast is managing heat around the core machine footprint. If we leave core boxes sitting cold or skip stable warm-up cycles, we risk part defects on the first rounds.

- Use warming systems or zoned heaters to balance cold air drift in open spaces

- Run warm-up cycles unloaded after first power-up to let parts expand slowly

- Seal ducts or fan paths near the machine to stop cold air from settling

- Keep control panels dry and covered during off hours to reduce condensation

Humidity is the hidden issue here. Cold air can carry moisture right into the tooling if the temp jumps too fast. That small fog layer might seem harmless but can interfere with parting lines, flash control, or even sensor reads on early cycles.

Spot management, like checking which areas are colder in the morning and warming them a little longer, keeps processes consistent. A bit of routine attention keeps the effects of rapid temperature changes at bay. Sometimes, keeping a simple shop thermometer at different stations is all we need to catch a pattern before it leads to part defects or changes in the cure cycle.

Lubrication and Airflow Setup for Cold Weather

Cold weather has a way of slowing more than people. When grease hardens and air restricts, small skips can feel like major flaws. That is why our daily checks double in value during colder weeks.

- Use cold-temp rated greases that hold flow even during early shifts

- Inspect key pivot points, slides, and actuator arms every morning

- Check airline pressure before shift starts and drain all water traps

- Purge lines that showed condensation the night before

Air must stay dry to work, but it also has to stay warm enough to expand and push evenly. That balance takes more effort in winter and will reset differently based on shop zones. We always look at where the chill lingers longer, especially near doors or exterior walls where frost collects faster.

Moving air tends to pull in cold from outside, which causes uneven performance on air-powered or servo-driven systems. Checking for drafts and ensuring ducts are clear helps machines run smoother. Adjustments to airflow can often be made without large investments, just careful observation and quick action. And while it might not seem urgent at first, even minor changes in airflow or lubrication can prevent a full line stoppage when productivity matters most.

Shop Layout Adjustments for Winter Flow

How we place our dual station core machines in the shop affects how they behave each season. Cold air does not move evenly, and it never leaves quietly. One side of the machine can warm faster than the other, throwing off motion or filling stages.

- Position machines away from open bays and high-traffic cold paths

- Block unused vents or doors to cut cold drift

- Add barriers between machines and thin shop walls where heat loss builds

- Make floor heating more even during startup, or limit placement near cold floors

Even a small change in ambient temp from one station to the next can create failures only on one side. We have seen side A strip clean while side B skips every third cycle when temp gaps creep past a few degrees. Alignment matters, but heat balance makes the bigger difference this time of year.

Taking the time to move machines or adjust their position by even a few feet can eliminate cold spots and lead to fewer unexpected stoppages. Evaluating potential cold traps in the shop each winter ensures your layout decisions are actually paying off when the weather is working against you. Look at natural air movement early each day, before equipment builds heat, to spot weak areas that need attention.

Save Time with Repeatable Winter Start-up Processes

Consistency pays off when cold sets in. A plan that works during warm months will not hold when fluids, materials, and bearings all respond slower. Repeating the same winter startup steps makes a difference we can feel by second shift.

- Post a startup checklist for each press or core system based on position in the shop

- Run press warm cycles with no load before production starts

- Cycle through basic motion systems to verify full range before casting parts

- Review clamps, ejectors, and lubrication points before the second cycle

Winter problems do not always show up right away. More often, they build with each cold start. We would rather take an extra 10 minutes than lose production later trying to chase a strip issue or timing misfire. Machines run better when they start slow, warm even, and move before they lift.

Rollout routines are a safety net for systems that can become unpredictable in the cold. By baking these steps into your daily prep, troubleshooting is easier and less costly. Even experienced crews benefit from reminders about uncommon checks on days when everything feels just a little tighter than normal. You cannot always see when grease is thick or air lines are sluggish, but returning to the same winter routine helps smooth out most of those early morning hiccups.

Keep Machines Running Smooth Through Winter

Core machines feel tighter when temperatures drop. That is just part of cold weather operation. But with the right prep, most of those slowdowns never show up in the day’s output.

Adjusting air, staying on top of grease flow, balancing layout heat, and repeating proven start practices keep our dual station systems in rhythm. When each station lifts smooth and stays timed, we hold schedule no matter the weather outside.

Routine checks give us room to fix small shifts before they grow. Winter may press us to rush, but steady patterns always win. With better setups and attention to where the cold hides, our machines stay ready and cycles keep flowing.

Winter can expose weak points in your workflow and slow down production more than usual, so evaluating your core equipment is important. By upgrading or fine-tuning your current setup, you can minimize downtime and keep cycle times consistent, even in colder conditions. At EMI Inc., our team has a proven track record of adapting layouts and tooling to quickly resolve challenges, especially when business demands intensify. To see how we maintain cold season efficiency with dual station systems, check our core machines. Let’s connect to discuss what is working, what is not, and how we can support your goals.