Guide to Winter Lubrication for Matchplate Molding Machines

Matchplate molding machines work hard through the winter, but colder weather affects more than just casting schedules. Lubrication often gets overlooked once production picks back up after the holidays. That’s usually when we notice small issues turning into bigger ones. Grease thickens, oil doesn’t flow the way it should, and start-ups take longer than usual.

A big part of keeping cycle times steady in February is knowing how cold impacts our setups. When lubricants don’t move well, molding machines lose efficiency and risk wear we could otherwise avoid. With the right plan, we can prevent cold-related stop-and-start issues and keep production running clean through the rest of the season.

Choosing the Right Lubricants for Cold Weather

Not all oils and greases perform the same when temperatures drop. Viscosity becomes the main concern, since thicker fluids can block flow paths or delay pressure buildup. If the oil stiffens too much, pump systems won’t circulate well. That leads to movement issues where constant motion is critical.

Synthetic oils often do better in cold settings because they remain more stable across temperature swings. Where conventional oils tend to lose flow below freezing, synthetics keep their structure longer. This helps keep load-bearing parts moving without sticky delays.

When it comes to grease, it’s not just about the base but the additives. For matchplate machines, we look for formulations that hold film strength, resist water intrusion, and stay soft enough to pump when stored near exterior walls.

- Use synthetic base oils rated for low-temp ranges

- Select lithium complex greases built for high pressure and low temp conditions

- Avoid heavy or multi-purpose products that slow under winter startup

The goal is to keep everything moving like it would in May, even when it’s February.

Preparing Internal Lubrication Systems for Winter

Before ice shows up outside, we check what’s already sitting inside our machines. Lubricants don’t age well if they sit too long or mix with dust or moisture. Cold only makes the problem worse, especially in parts of the foundry where airflow is limited and cold pockets linger through the afternoon.

Before cold fully sets in, we check oil reservoirs and circulation lines. Look for darkening of fluids, sludge buildup, or water separation that can limit flow once cold hits.

- Drain and flush reservoirs if buildup is present

- Replace strained or outdated lubricants with a known cold-performing alternative

- Adjust tank heaters, if installed, to keep oils in motion before startup

Grease lines on mold lifts or arm swings are easy to dismiss until something skips. Cold grease doesn’t just stop moving, it sometimes separates or gums up inside fittings. That’s why checking lines for signs of hardening or dry points early in winter helps avoid mid-season surprises.

Winter Adjustments to Lubrication Schedules

Lubrication checks done weekly in warm weather might not cut it when temperatures stay below freezing day after day. We bump up the frequency and shift based on what part of the shop is seeing delays. Some molding machines run near bay doors or thin-walled areas where the chill hangs longer in the morning. Others might face more startup issues only after weekends when lines sit idle longer.

Instead of treating every point the same, we split our system checks by function:

- Movement arms and slides near fans or vents need rechecking after long idle periods

- Hydraulic systems that warm slowly in winter benefit from shorter cycle reviews

- Mold carriers and guide rails build cold faster and need earlier grease renewal

A single cold spot can throw off timing across the setup. Zone-specific attention during peak winter keeps wear patterns from setting in deeper.

Operator Best Practices on Cold Starts and Shutdowns

A lot of small habits pay off during cold weeks. Most of what we see when machines don’t run smooth during the first few cycles of the day could’ve been caught during a check or warm-up pocket.

Before applying full speed or load, we rely on:

- Startup run-throughs where machines cycle unloaded and grease can spread

- Slower ramp-ups that avoid sudden fluid pressure when oil is still thick

- Walkarounds to feel for drag or tight turns in arms, links, or lift assemblies

Shutdowns matter, too. If machines are parked next to doors or under vents, metal parts cool fast, and so do lubrication paths. Without motion, grease weights settle and thicken. At end-of-day or Friday shift shutoff, we make sure covers are closed, moisture isn’t venting toward lube points, and heaters (if installed) aren’t disabled.

Cold Weather, Smooth Motion: What Consistent Lubrication Prevents

Cycle skips, jerky motion, or uneven stripping all trace back to parts not moving the way they should. When oil and grease are flowing right, matchplate molding machines almost feel like they’re running in spring.

That consistency is what we aim for. The right lubrication schedule, prep, and cold-specific products reduce downtime risk and stop wear from creeping in early. Cold alone isn’t what slows production, it’s how machines are prepped to handle it.

Even as we push toward the end of winter, we keep these routines in place. Most systems recover faster in spring if they weren’t dragged through February without enough attention.

By keeping things simple and steady, our lubrication game holds up through the toughest parts of the season. Less time fixing, more time molding.

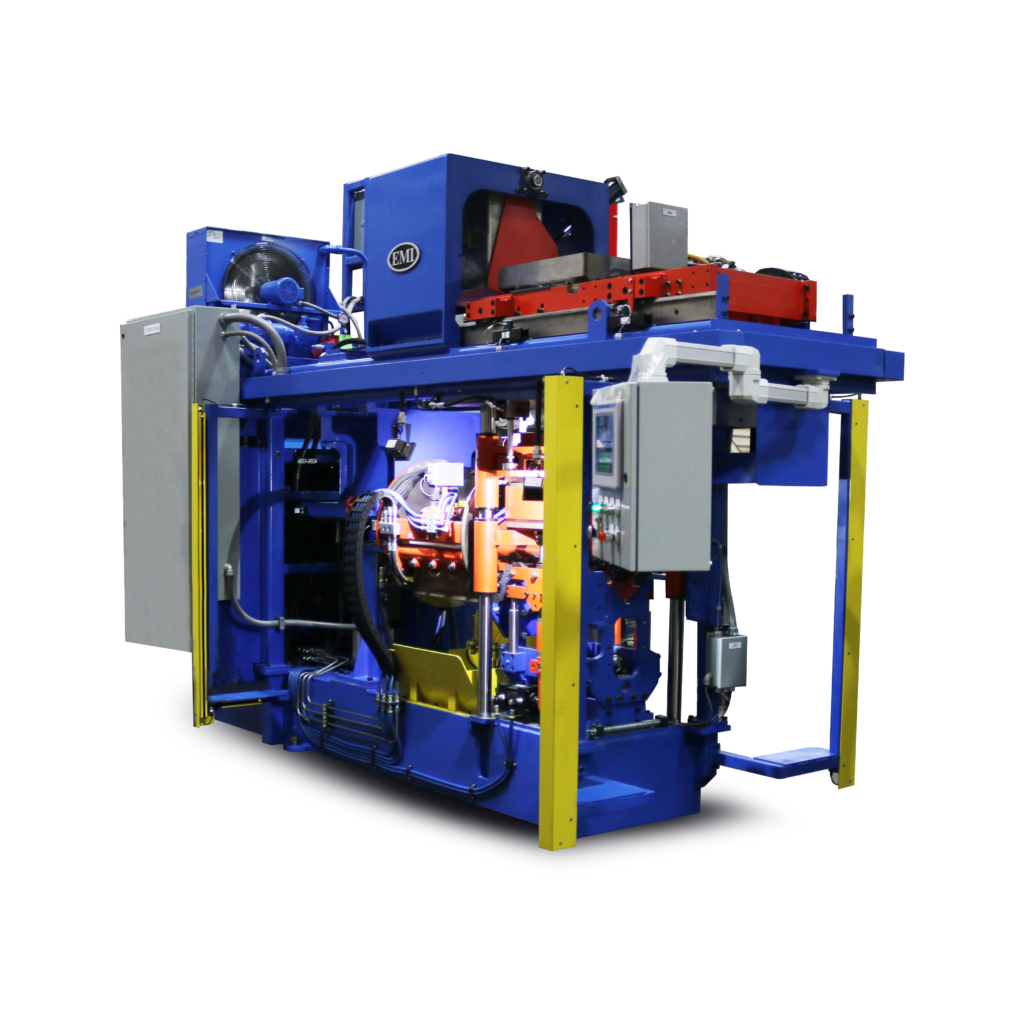

Cold weather can make daily operations more challenging, but a strong equipment foundation makes all the difference during winter months. We’ve seen fewer issues and quicker turnaround when our processes start with reliable components built to perform, even as lubricants and machinery face seasonal stress. For foundries aiming to improve consistency, now is a great time to see how our molding machines support production through colder conditions. Connect with EMI, we’re ready to discuss what’s working in your facility and help pinpoint opportunities for smoother operations.