When Is It Time to Replace a Core Machine’s Mixing Head

Mixing heads do heavy work on core machines. They blend sand, resin, and catalyst into the right mix for each core shot. But over time, wear and material buildup can change how they perform. If the mix goes wrong, the output suffers fast, and production lines can experience more downtime than expected.

When problems creep in, it’s easy to blame the system. But sometimes the root of the issue is right at the head. A worn or unbalanced mixer can throw everything off, causing all sorts of headaches, from inconsistent mixes to increased rework, rejected batches, and longer cycle times. Cores break easier, cycles drag out, and operators lose trust in what the machine will do next. Knowing when to replace the mixing head helps us save material, reduce rework, and keep daily production from stalling.

Signs of Unexpected Material Issues

We usually spot early signs in the materials we’re running every day. Even with clean lines, well-maintained equipment, and checked valves, if our resin or catalyst ratios drift, the issue could sit in the mixing head.

Watch for these signs:

- The blend isn’t consistent across shifts

- Cures vary more than usual, especially early in the day

- Surface finish starts showing small flaws, like dry patches or streaks

A damaged or partially blocked blade might not blend fast enough. That means not all the particles are fully coated or integrated, so sand, resin, and catalyst might hit the core box out of ratio, causing quality dips. Or, it may throw off parts of the catalyst stream. When that happens, one run might be fine while the next comes out too soft or not cured properly.

Those issues start subtle, but over days or weeks, you’ll notice a real dip in product quality. Operators might spend more time touching up, or even discarding defective parts. If you’re suddenly noticing more sanding, scraping, or patching, the mixing head is a good place to start checking.

Trouble During Production Cycles

Many of us have seen it: cycles slow just enough to feel off. Maybe it’s not enough to trigger an alarm or halt the line, but enough to make an operator pause. It could mean batches are taking longer to mix, fills are uneven, or discharge times are creeping up incrementally.

We pay close attention to:

- Interruptions during fill and shot cycles

- Extra air in the sand mix

- Unusual pressure or temperature during mixing

If there’s turbulence or backflow, that can mean internal wear is letting air into the stream. Over time, those small inefficiencies eat up shift time and cost material. Some operators notice more leaks, drips, or splatter. They start to clean up more often, but these mechanical symptoms usually connect back to wear in the head.

By the time we’re flushing more to clear the same heads, it’s usually a sign we’re chasing a mechanical problem rather than contamination. This can create a loop where production slows, cleaning time increases, and downtime for repairs eats into the usable hours of each shift. Sometimes the cause is obvious, like a noticeably stiff bearing or rattling noise during operation, but often, a tired mixing head is to blame for the performance drop.

General Wear and Maintenance Red Flags

Wear on a mixing head isn’t always visible right away. Over months, though, it shows up in how much time we spend tuning the machine, troubleshooting odd issues, or cleaning it out more than usual. Every foundry veteran knows the feeling of fighting with a stubborn machine, often the result of internal wear or buildup nobody can see without breaking things down.

We look out for:

- Erosion around blade edges or cracked liners

- Loose fittings or fasteners that don’t stay tight

- Recalibrations becoming more frequent or less stable

These kinds of problems may not stand out one by one, but collectively, they affect downtime and sand quality. The more frequently we strip down mixing heads for cleaning, the likelier it is that surfaces have rough spots, minor obstructions, or pitting. If fine materials stay stuck inside the head even after flushing, they’re likely building up in small rough spots or corners that used to be clean. That buildup throws off every shot and risks shifting the sand flow. It also puts strain on small parts meant to handle light loads, not gritty sludge.

After repeated cleaning and tuning, there is often a clear point where wear has gone too far. If we’re constantly recalibrating but not getting predictable runs, or if operators need to babysit a unit that used to run reliably, that’s a signal replacement is overdue. Eventually, wear hits a point where we spend more time working around the problem than fixing it. At that point, output has already taken a hit, even if the machine is still running.

Replacement Timing and Long-Term Planning

We don’t always have time for a full teardown. But patching a worn part for another few weeks tends to create more problems than it prevents. Early spring and the months ahead can get busy, so having spare heads ready and replacement time scheduled can make a real difference when things suddenly go sideways.

When deciding between continued repair and full replacement, we ask ourselves:

- How many parts or runs have been scrapped recently?

- Are we burning through more resin, sand, or time than usual?

- Can this be handled during scheduled downtime or shift changes?

Sticking to scheduled maintenance and replacement helps us avoid surprise breakdowns. If we’re working with a floor full of core machines, it helps to plan ahead. Swapping out mixing heads a few at a time avoids full shutdowns and spreads out the cost, so budgets stay in line. Some shops stagger replacement to match operator training or maintenance schedules, which also helps protect output and reduces the chance of a missed cue.

Predictable replacement schedules can give operators more confidence in their equipment and process. Even minor tweaks help keep the flow steady. During peak times, if a mixing head does fail, that preplanning turns a potential crisis into a quick fix with minimal impact.

Plan Replacement with the Right Partner

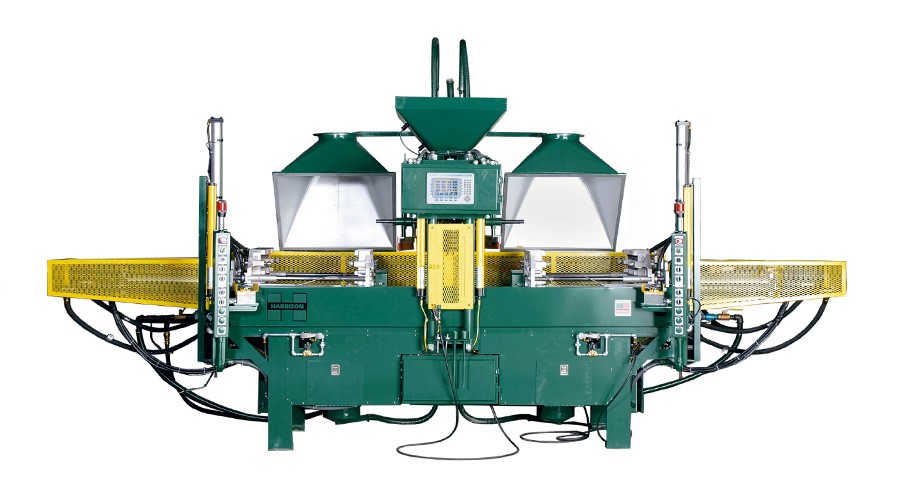

When it’s time to act, choosing the right replacement parts can streamline your transition. EMI designs replacement mixing heads specifically for our cold box core machines, ensuring compatibility and high performance. Many EMI mixing heads and blades are engineered for quick changeout, reducing downtime and improving safety, so production goals are met even during upgrades.

A good mixing head makes everything behind it run smoother. When material quality holds, cycles stay predictable, and operators trust the process. But the more we push a worn head, the closer we get to downtime and added cleanup.

By keeping an eye on performance early and making a plan before a failure happens, we stay ahead of shifting cycle times or bad cores. Replacing a mixing head at the right time won’t just fix the surface problems. It keeps the whole floor running at the pace we expect.

Keeping your operation running smoothly means being proactive about equipment maintenance, especially when it comes to your core machines. At EMI, we know the signs that lead to production bottlenecks and casting challenges, and our team is ready to help you address any concerns before they affect your workflow. Let us support you in maintaining the reliability and efficiency that your customers expect every day.