Everything to Know About Manual Molding in Cold Weather

Manual molding doesn’t stop just because the temperature drops. For foundries running through winter, the cold adds a layer of difficulty to an already hands-on process. Low temperatures can change how quickly metal solidifies, but they also affect how molds are made in the first place. When cold air creeps across the shop floor, it has a way of showing up in slower pace, inconsistent compaction, or even frozen equipment. This includes all types of molding machines, from classic manual setups to Osborne matchplate systems.

We have worked through enough winters to know that a few smart adjustments can help keep manual molding processes steady through January and February. It is not always about adding heat. Sometimes it is just about working more intentionally around the cold.

How Cold Weather Affects Manual Molding Processes

The first thing we usually notice when winter settles in is how sand behaves differently. What used to flow easily might now feel heavy or sluggish. That can lead to shallow impressions or soft edges in the final mold. When bond strength suffers, the chances of part defects start to go up.

Tooling can add delays too. If a rack or plate sits overnight in cold air, it draws down the temperature of the sand upon contact. Fill times take longer. Workers often have to wait for surfaces to warm up or deal with variations in initial compaction. These are not just minor shifts. They impact cycle time and mold repeatability across a shift.

Hands-on work also slows down. Gloved handling, fatigue from working in cold, and adjustments to pace and position all affect output. It is small changes that add up. Over a full day, they can throw off the rhythm that manual molding teams rely on.

Workspace and Equipment Considerations for Cold Days

Having the right workspace makes a measurable difference in staying productive during cold spells. One of the simplest things we can change is airflow. Drafty doors or unsealed vents pull cold air right into places where molding happens. Those gusts do not just chill workers. They cool patterns and sand mixes, even during operation.

Some manual systems have exposed parts that are more sensitive to freezing temps. Wrapping plates or adding warming blankets to resin chambers can prevent long startup delays in the morning. These small steps help avoid frozen lines or thickened materials that slow everything down.

Placing molding machines closer to interior walls or low-traffic heat zones helps, too. It is not about a big layout overhaul. Just moving away from cold-prone sections of the floor can give operators an easier, faster start to their cycles.

A well-organized workspace also keeps tools and molds ready for use by cutting down on time searching for parts that might have gone cold sitting out. Quick access to prepped surfaces speeds up cycle times and cuts unnecessary delays.

Sand Handling and Conditioning in Cold Months

Sand will almost always behave differently in winter. Even if your moisture levels are under control, the lower temperatures change the way sand bonds and fills. Cold sand does not compact the same way. Patterns may not fill completely without extra effort or repeat passes.

Preheating the sand (when that is possible) gives molding teams a major advantage. It evens out the feel during fills and supports better compaction without extra pressure. It also makes venting and stripping more consistent.

Storing sand properly matters, too. If sand sits overnight where open air or condensation hits it, there is a chance it hardens or forms clumps. That throws off the mix and flow rate the next day. Keeping bins covered and protected from cold exposure helps reduce frozen buildup at the bottom. The goal is steady temperature and easy movement, so your first fills of the day match the last ones.

Sand condition needs to be checked more frequently in winter. Sample the sand throughout the shift to catch any changes early. If adjustments are required, make them in small increments to avoid sudden changes that could affect mold quality. Regular mixing and testing keep the blend uniform as temperatures change through the day.

Adjusting Manual Routines Without Sacrificing Quality

Cold weather does not mean having to settle for lower quality. But it may mean adjusting the way those quality steps happen. For teams working manually, timing matters. Making small changes to the daily routine can help make winter cycles feel more predictable.

- Staggered pattern prep helps keep jobs moving. Start warming or setting one while the previous mold cures or finishes.

- Built-in wait times before stripping or pouring reduce surface damage caused by cold tools or chilled sand.

- More frequent checks of edges, parting lines, and vent paths stop problems before they become larger defects.

The wear on tools and patterns can also increase during cold use. Adding short downtimes or rotating through pattern sets helps prevent sticking and deformation. Heat loss during transfer is real, and every step should account for the drop in mold temperature from filling to finish.

Include team communication in routine adjustments. Share observations about how the process feels each day, so shifts can spot patterns or anticipate slowdowns. This keeps everyone prepared for consistent winter production.

Keeping Production on Track Through Winter

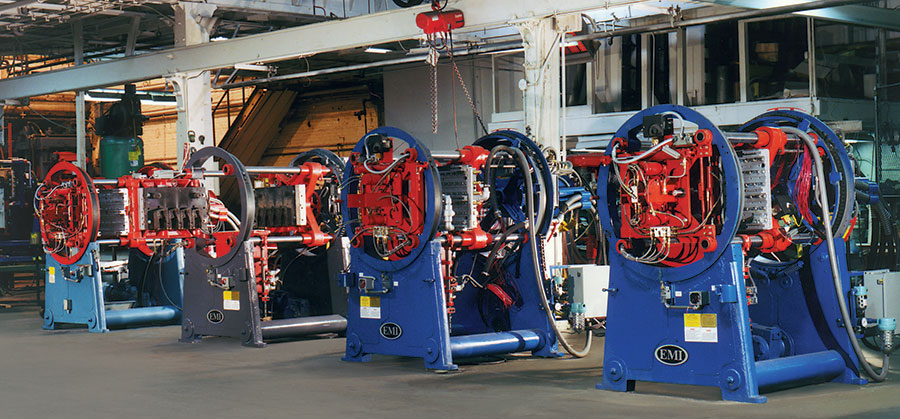

EMI supplies both Osborne and custom-built manual molding machines that are engineered for durability and consistent operation in foundry settings. Many EMI manual molding systems feature robust frames and replaceable wear components, supporting long-term reliability through temperature extremes and heavy use. EMI backs these solutions with technical support, helping foundries maximize productivity no matter the season.

Weather is not something we can control, but the way we work through it can be managed. The key is not pushing harder, it is working more consistently with the way winter changes our equipment and materials.

By adjusting routines, focusing on sand quality, and keeping molding machines in better working conditions, we reduce delays and scrap. Even when the floor feels cold, production does not have to stall. With the right habits and tools dialed in for January, we keep our pace steady regardless of the temperature outside.

At EMI, we understand how cold seasons can challenge not just your equipment but your entire operation. The right tools and adaptable routines often mean the difference when every degree on the floor impacts compaction, flow, and timing. As you reevaluate your processes for winter, consider the impact your molding machines have on maintaining steady output. Simple adjustments in equipment setup or workflow timing can help reduce scrap and downtime. Let us help you explore solutions to keep your operation running smoothly when the temperature drops.