Cold Weather Impact on Molding Machine Performance

Winter brings more than just lower temperatures. It delivers challenges for foundries that rely on precise, stable workflows. When your molding machines are exposed to cold conditions, their performance can drop without warning. Even small changes in temperature can have a noticeable effect on how machinery behaves, especially during long runs or overnight shifts.

While downtime during warmer months might be easier to notice and address, cold weather triggers hidden problems that can pile up without being immediately obvious. From thickened hydraulic fluid to unreliable sensors, minor slowdowns can lead to real production delays if not handled early. Knowing how winter affects equipment performance makes it easier to plan ahead and prevent headaches.

Effects of Cold Weather on Molding Machine Components

Cold doesn’t just make the shop floor uncomfortable. It changes how your machines perform. Molding machines, especially those that operate continuously, depend on stable temperatures for optimal efficiency. When the shop gets cold, the effects start to show—especially on the most critical machine parts.

1. Hydraulic Systems Get Sluggish

Cold temperatures slow down hydraulic fluid. When fluid thickens, it flows slower, reducing system pressure and affecting cycle times. This lag puts stress on pumps and other components, potentially shortening their lifespan while causing output delays.

2. Lubricants Lose Their Effectiveness

Oils and greases are less effective when they’re cold. Thicker lubrication means less flow and more friction. Moving parts like pistons, cylinders, and clamps face more resistance, which wears them down faster and causes uneven motion or sticking.

3. Electrical Components Become Sensitive

As temperatures shift, condensation can start to form—especially when the machine begins running in a cold room. Moisture can build up in control panels, sensors, and connectors. This leads to short circuits, misread sensors, and inconsistent behavior. Cold temperatures may also throw off calibration, reducing the reliability of automated and feedback systems.

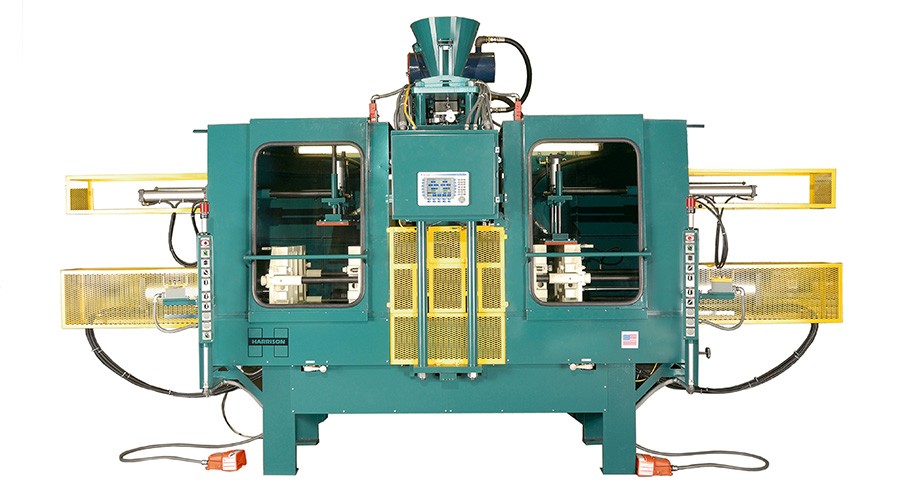

Picture this scenario: you’ve got an automatic matchplate molding machine running before dawn on a frosty morning. It fires up, starts the first batch, then gradually slows. A quick look shows no major issues, yet production is behind. The problem? Cold hydraulic fluid that hasn’t reached operating temp. Small delays like that, shift after shift, can begin to add up.

Knowing when and how cold affects each part of your machine is the first step to limiting losses. When you identify temperature swings as the cause, it’s easier to act sooner and smarter.

Preventative Measures for Cold Weather

Waiting for parts to break costs time and money, especially when cold weather is involved. Preventative steps taken daily or weekly can keep your molding machines functional and productive throughout winter.

Start with thorough inspections. During winter, even minor cracks or leaks in hoses, fittings, or electrical panels can cause bigger trouble. Check machines at the start and end of each shift. A few extra minutes per check beats hours of downtime.

Switching your fluids is another smart move. Standard lubricants often underperform when cold. Use low-viscosity or cold-rated alternatives that flow better at lower temperatures. This reduces friction and protects parts from excessive wear in cold starts.

Moisture control is key. Electrical systems are more vulnerable once condensation creeps in. Check that covers and enclosures are tightly sealed and positioned away from direct airflow. For sensitive parts, try insulated or heated housings, especially for sensors and control circuits.

Stick to these cold-weather basics:

– Inspect moving parts and hoses daily for damage or wear

– Replace standard fluids with winter-rated alternatives

– Drain and dry compressed air systems to prevent freezing

– Keep wiring and electrical enclosures clean, dry, and insulated

– Store spare parts in heated areas to prevent freeze damage

Doing these tasks routinely—even when you’re busy—pays off by improving reliability and reducing emergency repairs.

Best Practices for Operating Molding Machines in Winter

Running molding machines in colder months requires a few changes to your usual routine. These don’t need to be major, just focused on making your system more forgiving when conditions get rough.

Cold starts are particularly tough. The sudden demand placed on thick fluids and cold mechanical connections can lead to pressure spikes and wear. A good habit is to run a short warm-up cycle before heavy production. Allow pumps and motors to operate under light load for several minutes, letting fluids reach functional temperature before ramping up speed.

Your environment matters just as much. Drafts and cold surfaces affect machines more than most people realize. Move equipment away from outside-facing walls, keep dock doors closed when possible, and block cold airflow near control boxes or sensor arrays. Keeping a consistent indoor temperature helps the whole process run smoother.

Apply some of these best practices each shift:

– Begin each day with an idle warm-up cycle

– Preheat tooling and molds before production use

– Limit exposure to drafts and temperature swings

– Use thermal covers or barriers for exposed controls

– Monitor operations using temperature sensors when possible

Don’t overlook your operators either. Low indoor temperatures can cause crews to rush warmups or miss signs that something is off. Reinforce slow and steady processes when temps fall, and make sure everyone knows how cold affects the machines they work with.

Preparing Your Foundry for Winter Operations

Keeping your machines ready is one thing. But to stay ahead this winter, your entire foundry environment should support smooth operations.

Start with temperature monitoring. Install shop floor thermometers in key areas and use local heaters to control problem zones, such as hydraulic stations, control panels, or tooling storage sections. Avoid placing sensitive systems near exterior doors or windows.

Training goes further than just safety. Many seasonal operators don’t realize how equipment behaves differently during cold weather. Teach them how to spot temperature-related wear, how to perform cold starts, and when to flag performance issues.

Winter planning also includes stocking critical parts. Delays in shipments are common in colder months. Keep hoses, seals, filters, and fluids on-site. Be ready for unplanned repairs.

Organize your foundry winter plan around:

– Monitoring indoor temperatures and adjusting as needed

– Reviewing cold-weather procedures with equipment operators

– Keeping parts inventory topped off before the season peaks

– Maintaining daily checklists for wear or signs of cold-related failure

– Setting repair steps that account for winter-specific issues

The more prepared your facility is, the more you’ll reduce stress on your equipment and team when outdoor temperatures drop.

Keep Cold From Slowing You Down

Winter always brings a few bumps along the way, but those bumps don’t have to slow down your production. Knowing how cold impacts your molding machines gives you the upper hand.

From slow hydraulic systems and stiff lubricants to mistimed sensors, cold issues add up fast if ignored. That’s why sticking to regular inspections, following warm-up steps, preparing your space, and training your crews can make a world of difference.

Build your schedule around the season, take extra care with parts and procedures, and communicate clearly with your staff. These habits lead to stronger performance and fewer setbacks—no matter how low the temperature drops.

To keep your production moving smoothly throughout the colder months, focus on maintaining system readiness across the board. Regular inspections, cold-rated fluids, and a temperature-stable environment all help avoid unexpected interruptions. EMI offers practical support to help you stay ahead of seasonal challenges. Learn more about our solutions for molding machines built to handle winter’s demands.