Adjusting Mold Thickness For Better Molding Machine Output

When it comes to molding machines, even slight changes to mold thickness can impact how well the machine performs. It might seem like a small adjustment, but getting the thickness right plays a big part in output, consistency, and long-term durability of both the equipment and the final product. If you’re not paying attention to this, you’re likely leaving efficiency and quality on the table.

Adjusting mold thickness can bring real benefits. Faster cycle times, fewer defects, better surface finish, and more predictable output are just a few. It can also lower the chances of rework, reduce stress on machine components, and limit downtime caused by misalignments or strain. For operations that use manual molding machines or fully automatic matchplate systems, dialing in the right mold thickness can lead to noticeable savings in time, material, and labor over the course of a production run.

Understanding Mold Thickness

Mold thickness refers to the overall depth of the mold cavity along with the surrounding support sections of the mold. It’s tied directly to how the machine compacts and shapes sand around the pattern. Machines like manual matchplate molding setups or automatic tight flask systems rely on this consistency to deliver repeatable results. Get it wrong, and you might deal with poor compaction, weak molds, or even faulty castings.

Several things influence what the right thickness should be:

– Type of metal being cast

– Sand properties and binder type

– Machine design and power

– Part geometry and production run size

For example, high-pressure automatic tight flask systems may require tighter control of thickness compared to lower-pressure manual systems. Molding a simple brake drum is not the same as producing a large industrial housing. Thicker molds provide more strength for larger castings, but they can also slow cycle times or cause stripping issues. Thinner molds may speed up production, but they tend to be less forgiving when it comes to core placement or venting.

Whether you’re working with ferrous or non-ferrous metals, fluctuating mold thickness can lead to inconsistent compaction. This affects everything down the line, from flash formation to surface roughness. Core machines, especially larger dual-station or QuickCore types, can also be impacted if mold thicknesses aren’t accounted for. Even prototype and manual systems need careful monitoring to avoid overworking the pattern plate or stressing the strike-off bar.

Methods For Adjusting Mold Thickness

How you adjust mold thickness depends on your molding setup and the kind of casting work you’re doing. Manual machines give operators more direct flexibility, while automatic systems usually require changes through a control interface or mechanical shimming.

Here are some common methods used to adjust mold thickness successfully:

1. Manual shimming: Operators can add or remove shims to adjust the spacing between pattern plates and flask surfaces.

2. Hydraulic or pneumatic controls: Common in automatic systems, where the machine self-adjusts based on programmed thickness values.

3. Mechanical stops or locks: These can be preset to control the travel range of rams or molds to avoid over-compression.

4. Core setting adjustments: In cold box core machines, like the 3-IN-1 or dual-station models, slight changes in blow pressure or core box spacing can help align cores with varying mold thicknesses.

5. Pattern plate changes: In some cases, different plate models may be used to support a specific mold cavity depth.

To do it right, follow a few basic steps. Start by reviewing the casting specs. Then, check your flask or matchplate pattern for wear or deformation. For automatic machines, verify control settings. Manual machines may require you to visually inspect the mating surfaces and measure depth regularly. Don’t overlook pressure checks for hydraulic settings. They play a big role in delivering even compaction across different mold sizes.

Tips for adjusting thickness by machine type:

– Manual molding machines: Keep calipers or depth gauges handy. Be patient when fitting shims or locks. It’s better to tweak in small steps than to overshoot.

– Automatic matchplate systems: Use your control system to set mold height. Confirm that feedback sensors are clean and calibrated.

– Tight flask molding machines: Double-check flask wear patterns and mold alignment frequently, especially when running back-to-back shifts.

A good rule of thumb: if you’re seeing uneven flash, off-center cores, or dips in surface texture, it might be time to check your mold thickness. Machines don’t always give an alert. Small issues add up quietly until they cost you a lot more in output.

Impact Of Mold Thickness On Machine Output

Mold thickness doesn’t just affect how the sand packs. It directly influences your production rate, machine efficiency, and casting quality. If the mold is too thick, the machine may spend more time pressing and compacting the sand than necessary, leading to slower cycle times. A mold that’s too thin may not offer enough strength, which puts parts at risk for collapse or defects during pouring. Either extreme chews up time, material, and resources.

Casting quality is also on the line. An inconsistent mold thickness often results in dimensional issues, rough mold surfaces, and even improper core fit. These problems creep in slowly, but their long-term impact can be expensive. Misshapen castings, extra grinding, or re-pours can pile up, especially on longer runs.

Take, for example, a foundry using dual-station cold box core machines alongside automatic matchplate molding machines. They began getting surface defects and irregular parting lines. After a quick review, it turned out that their flask wear had quietly shifted the operating thickness. By recalibrating mold height settings and adjusting pressure points in the matchplate sequence, they tightened cycle times and completely eliminated the surface flaws. That single tweak cut down on wasted casts and smoothed out production flow with minimal downtime.

Optimal thickness gives an even pour path and supports proper venting. That helps avoid gas-related defects and keeps your cores stable during the fill. With machines like QuickCore or 3-IN-1 setups, where parts are often complex and time-sensitive, every part of the mold, including thickness, needs to be dialed in properly to keep operations efficient.

Maintenance Tips To Preserve Mold Thickness Settings

Maintaining consistent mold thickness over time comes down to a mix of smart maintenance and regular checks. The more consistent your mold packing remains, the more steady your output.

Here’s a basic list to help you keep mold thickness settings in check:

– Inspect pattern plates for wear or surface damage during shift changes

– Check flask faces and locking mechanisms weekly to catch early signs of warping or play

– Clean buildup off matchplates and tooling surfaces to keep contact areas uniform

– Verify thickness settings during any major changeover or when material types shift

– For automatic setups, calibrate sensors and cylinder strokes monthly or as needed

– Mark adjustments clearly in operator logs to help flag unusual changes or deviations

Manual machines demand closer daily attention, as their components experience more direct wear and movement. Automatic matchplate and tight flask systems may run smoother for longer, but even they can drift out of alignment without warning if sand buildup interferes with the set points.

Tools like depth gauges, feeler gauges, and regular alignment checks are small steps that make a big difference. A simple missed shim or blocked sensor might not show up until it has already dragged down multiple shifts’ worth of castings. Building these maintenance habits into your process helps your crew stay ahead of the problems rather than reacting to them.

Why It Pays To Get Mold Thickness Right

Getting mold thickness right isn’t just about fixing a weak spot in your process. It’s about setting yourself up for lasting reliability and better-performing equipment. Machines that consistently stay within their mold thickness spec generally wear down slower. That leads to fewer emergency repairs, more uptime, and a smoother routine overall.

You’ll also see a steady impact on casting quality. When your mold thickness is under control, you cut down on rework and catch fewer surprises after shakeout. That helps with deadlines and makes it easier to fine-tune other parts of your operation.

Another plus is machine protection. Whether you’re working at a manual molding station or running Savelli automatic tight flask lines, getting thickness dialed in cuts the stress on the machine. That means less strain on rams, fewer issues with aeration, and more consistent performance from binders and additives.

Finally, confidence across the team goes up. When operators can trust their setup, they spend less time troubleshooting and more time doing their best work. New hires get up to speed faster. Consistent mold performance gives your entire line a stronger foundation.

A regular mold thickness check and a few smart adjustments can be the difference between a good shift and a costly one. Take the time. Lock it in. Your machine output will thank you.

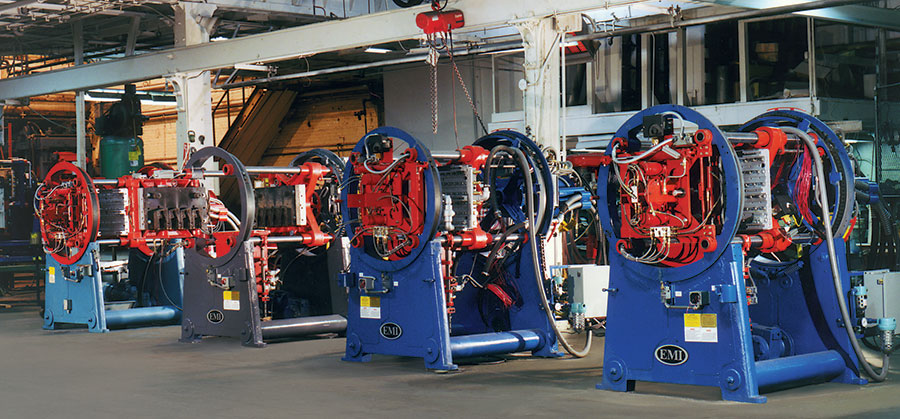

For foundries looking to improve production efficiency and casting quality, mastering the art of mold thickness adjustment is key. It’s not just about short-term benefits; it provides the long-term stability needed in high-demand environments. Explore how optimized setups for molding machines can help you streamline output and reduce downtime, backed by the experience and support of EMI.