Core Machine Blow Pressure Optimization Tips

Blow pressure plays a major role in how well core machines perform during the core-making process. When it’s set and controlled the right way, blow pressure helps fill core boxes evenly, minimizes material waste, and improves how fast and clean the cores come out. Skimping on blow pressure control can lead to weak cores, sand blowouts, or inconsistent shapes that set off a chain of problems all the way down the line, especially when production is moving fast.

For metal casters, dialing in the right blow pressure is more than a machine setting. It’s a step that affects overall cycle time, tooling wear, and part quality. Whether you’re running automatic systems or working with manual setups, small tweaks to blow settings can make a noticeable difference. This article focuses on how to understand, manage, and improve blow pressure so you can get more consistent results across your core machines without the headache of trial-and-error guessing.

Understanding Blow Pressure in Core Machines

At its core, blow pressure refers to the amount of force used to push sand into the core box during the blowing cycle. In a cold box core machine, for example, this pressure determines how fast and how fully the sand fills all areas of the box before gassing and curing take over. When the pressure is too low, you end up with cores that are soft, incomplete, or structurally weak. If it’s too high, you’re more likely to see flash, tool wear, or even damage to the equipment.

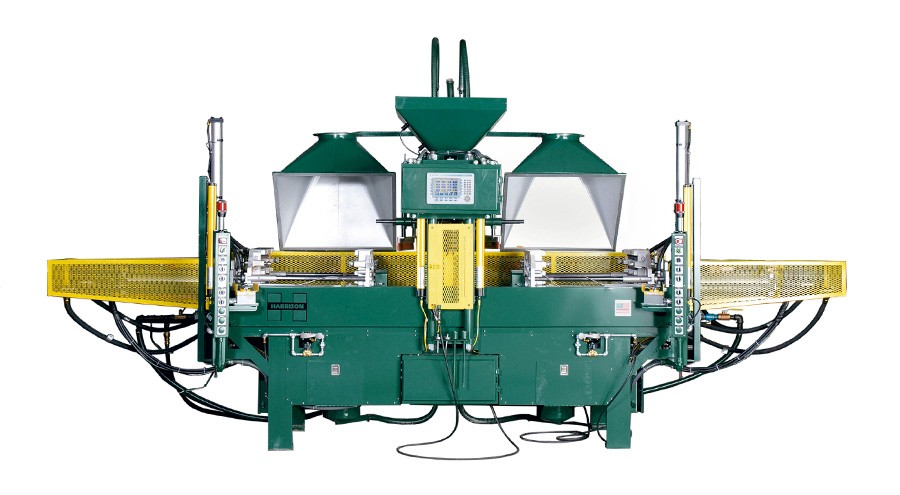

Each machine type and sand mix has its own blow requirements. A dual station setup may tolerate different ranges compared to a single station or QuickCore system. What matters most is choosing a pressure that lets the sand flow evenly, avoiding dead zones or random compaction. Some operators forget that atmospheric conditions can also influence how sand responds to pressure. For instance, warmer shop temperatures or drier air can make sand flow quicker than expected, requiring adjustments to avoid over-packing or clogging.

Take this simple example. A foundry using the same blow setting across different boxes noticed varying core defects on different molds. After digging deeper, it turned out that the core boxes had slightly different venting layouts. Adjusting the blow pressure per box, rather than using one setting for all, helped balance sand filling and ended the cracking issues without any other changes. That’s the kind of fine-tuning blow pressure control can give you.

Key Factors Influencing Blow Pressure

Blow pressure can feel a bit unpredictable unless you know all the pieces that affect it. Controlling it well doesn’t have to be complicated once you understand what drives the outcome. Here’s a look at some of the core factors that come into play:

1. Sand Characteristics

– Finer sands require less pressure for good fill but are more sensitive to humidity and temperature.

– Coarser sands need higher pressure and clear venting due to their larger grain shape.

2. Tooling and Core Box Design

– Poor vent layout or uneven cavity sizes can block flow or cause short fills.

– Worn tooling or clogged vents throw off the filling pattern, even if pressure settings remain the same.

3. Machine Settings and Timing

– The speed and duration of the blow cycle matter just as much as the pressure itself.

– A quick spike in pressure can help at the start of fill, but too fast a ramp can blow sand past the mold detail.

4. Environmental Conditions

– Shop temperature, humidity, and compressed air quality all affect how sand flows with a set pressure.

– Seasonal changes may require micro-adjustments even without changing patterns.

5. Maintenance Practices

– Dirty sensors, leaky lines, or air blockage can throw off readings and reduce actual output pressure.

– Gauge calibration should be part of regular checks, especially when issues become frequent or unpredictable.

Because of all these moving parts, it helps to set up a few standard checks for any new job or core box, even if you’ve used the same machine settings for months. A slight tweak to match fresh sand or a different environmental change can save hours of rework or scrap. Getting comfortable with pressure tuning can help you stop problems before they show up at inspection.

Best Practices for Blow Pressure Optimization

Getting consistent blow pressure results doesn’t hinge on one change. It comes down to a set of habits that keep machines running smoothly and help crews spot when something’s off. Whether you’re running high production cold box machines, dual station setups, or even manual or prototype systems, the approach stays focused on clear results.

To keep things on track, here are some helpful practices:

– Set baseline pressures for each core type and update them when switching patterns or boxes. Don’t rely on remembered numbers. Write them down where everyone can see.

– Attach pressure gauges that are easy to access. A bad reading can waste time checking parts that aren’t the issue.

– Run a fill test on new molds before going into full production. A few test blasts at lower pressure can highlight uneven pack areas or venting trouble.

– Watch the sand fill and venting visually if possible. Many operators spot problems when they observe a few cycles after setup.

– Clean the air delivery system on schedule. Some machines struggle to maintain pressure because of worn valves or air leaks you can’t hear.

– Keep a maintenance log specific to blow systems. This helps spot pressure drift patterns and track changes across shifts or batches.

– Use the right sand mix for the job. If particle size or moisture shifts unexpectedly, even good settings won’t hold up.

These habits give operators more control over shifting variables and reduce run-time problem solving. Over time, these checks become part of the routine and help smaller shops stay just as dependable as larger operations.

Common Blow Pressure Issues and Quick Fixes

Even with a solid setup, blow pressure problems can still show up. When the fix isn’t obvious, small signs like slower cycles, vent noise, or sticky cores tell you where to look. Having a list of common problems means you’re less likely to spin your wheels guessing.

Here are typical issues and where to start:

– Weak or incomplete cores: Check for under-blow from clogged filters, low tank pressure, or air leaks in the feedlines. Tooling vents are another suspect, especially after a tooling change.

– Sand flash around core edges: Usually caused by high blow pressure or poor fixture alignment. It could also mean the sand mix is too dry or overly fine for your mold design.

– Inconsistent fill across shifts: Often related to airflow. Double-check compressors and regulators for consistent output during heavy demand. A drifting gauge or clogged filter can quietly throw things off.

– Frequent tool wear and gasket damage: Too much pressure can be the root cause. Scale it back and inspect your timing. If a pre-blow is too short, sand can hit weak spots hard before settling properly.

– Slow core release or sticky tools: May point to uneven venting or a sand mix that holds on more than expected. Vent pattern and placement may need adjustment, not just pressure levels.

Tackling these problems works best with small, goal-oriented changes. Avoid jumping to change every setting at once. Link the issue to a possible cause, adjust one item, then test. Lots of experienced crews keep a basic checklist handy so they don’t waste time retracing steps.

Improving Core Results One Adjustment at a Time

Optimizing blow pressure isn’t about chasing some perfect number. It’s about finding settings that deliver consistent performance, better part quality, and fewer interruptions on the floor. Whether you’re using automatic matchplate equipment or testing out a new mold on a prototype bench, understanding your blow settings is one of the fastest ways to improve results.

These problems rarely hit in isolation. One small change in sand blend, a slightly loose clamp, or a worn hose can all start a chain reaction. The good news is those same small adjustments, when made right, lead to smoother runs, cleaner cores, and less waste.

Even older machines can meet high expectations when attention is given to blow pressure controls. A team that logs changes, reacts early to symptoms, and stays close to the process will always be in a better spot. And when bigger shifts come—like volume changes, new equipment, or complicated jobs—having that control built into the setup gives shops the confidence to keep pushing forward.

If you’re looking to improve casting quality and reduce downtime, adjusting how you manage blow pressure in your core machines is a smart place to start. EMI offers reliable solutions and expert guidance to help your foundry run cleaner and more consistently with less guesswork. Let us help you fine-tune your operation for better results.