Upgrades That Improve Molding Machine Performance

Molding machines help shape foundry output at every step, from cycle times to part quality. When they’re operating as they should, they can save time and labor while improving repeatability. But like any machine, they can lose performance over time or fall behind newer technology. The result is usually slower production, poor castings, or higher downtime. If you’ve noticed any of these, it might not be the operator or the shift—your machine might just need an upgrade.

As shops head deeper into automation and digital control, molding machines have the potential to do more with fewer resources. The tech inside these machines has come a long way in just a few years. Upgrades aren’t always about buying a whole new unit. Sometimes, simple refits make the biggest difference. Whether it’s smoother interface control or energy-saving parts, even small changes can have a measurable impact. If your shop is running aging systems or you’ve pushed production limits recently, it might be time to take a fresh look at what upgrades could do.

Identifying The Need For Upgrades

When molding machines slow down or make more mistakes, it’s easy to blame maintenance or materials. But sometimes, the real issue is the machine itself. Older models or those without software updates struggle to keep up with evolving job specs or tighter tolerances. These slips start small, but they build over time. Spotting the signs of lagging performance early gives you a better chance to upgrade before bigger issues show up.

Watch for these signs that might indicate it’s time for a change:

– Longer cycle times even with steady conditions

– Rising scrap or rework rates

– Trouble keeping consistent temperature or pressure

– Outdated controls that don’t support newer software

– Operators working around the machine’s faults instead of with it

If you’re seeing more than one of those regularly, your output is likely taking a hit, whether you’ve noticed it yet or not.

Aside from solving problems, upgrades are also about possibilities. They let your team move faster, reduce errors, and prep for future production needs. Staying current means less risk of surprise downtime or unplanned replacement. It’s a more proactive way to keep jobs flowing, even as materials or specs change.

Key Upgrades To Consider

Upgrades vary depending on the size and type of your molding machines, but certain improvements stand out. Shops working with manual or Osborn matchplate molding machines, for example, often benefit from better ergonomics and more consistent clamp force. Those running automatic matchplate systems or tight flask molding lines may get more value from control software and servo improvements.

Here are some common upgrades that can bring strong returns:

1. Modern Control Systems

Switching to updated controls or software platforms can make operating the machine easier and more precise. Newer systems improve real-time feedback, scheduling, and operator interaction. This can reduce set-up time, errors, and improve syncing between multiple stations.

2. Enhanced Automation Features

Adding automation like automatic core setting or automated clamping opens up production volume without needing more hands. These features help machines run longer with less direct oversight, which can support multi-tasking or lights-out shifts.

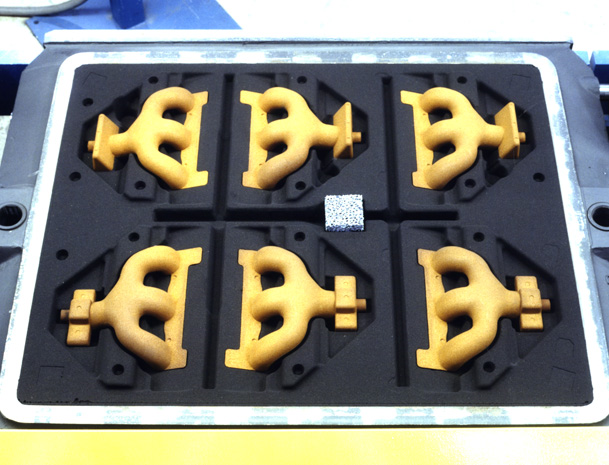

3. Improved Tooling And Dies

Upgrading tooling materials or designs can limit wear and extend die life between changes. Some newer die materials also hold shape longer under heat and stress, which leads to cleaner casts and better product consistency.

4. Energy-Efficient Components

Modern shutdown functions and variable-speed motors can trim down the energy cost per cycle. These parts often pay off over time by reducing power use during idle or low-load periods.

Not every upgrade fits every job. That’s why it helps to measure current issues first and match your machine’s needs to the upgrades that solve those specific pain points. Trying to change too much at once can also create issues for training or process flow, so it pays to take a thoughtful approach.

Implementation And Integration Tips

Adding upgrades to molding machines is more than just swapping parts. There’s a process that keeps things running smoothly during the change. If upgrades are rushed or poorly timed, production can get thrown off, even if the parts themselves are a better fit. Planning and prep are what make the difference.

Start by working closely with your operators and maintenance team. They know how the machines behave daily and can guide what upgrades will help the most. Once you’ve decided on the right solutions, the next steps matter just as much:

– Schedule upgrades during planned downtime or slow periods

– Run mock-ups or dry cycles using the new system or tooling

– Document changes made so future issues can be tracked

– Assign one or two lead operators to test the upgraded setup first

– Keep a backup plan in place should anything need to be rolled back

Some shops miss out on value because they overlook training. If staff members aren’t comfortable with the new tools or control systems, performance could actually dip. That’s why a solid roll-out includes hands-on training for the machine’s updated functions.

An example of poor rollout might be upgrading to energy-saving servo systems but leaving legacy controls in place. While the hardware improves energy use, the operators are now dealing with mismatched systems that don’t communicate properly. The result is downtime and a frustrated team. Making sure all parts of the machine work together helps avoid issues like that.

Upgrades are only as good as the setup behind them. Test, train, and track your changes. Changes that are better planned will last longer and return more value.

Choosing The Right Partner For Molding Machine Upgrades

The success of any upgrade depends on who you work with. From core machines to molding lines, metal casters need more than parts—they need support and guidance. Not every supplier or manufacturer has the expertise to deliver both.

Here are a few things to look for when choosing a partner for upgrades:

– Do they offer support for your current machine model?

– Can they recommend upgrade paths based on your exact production goals?

– Will they provide installation, testing, and operator training?

– Do they carry upgrade kits or work with modifications for both older and newer machines?

– How do they handle service or repairs if something doesn’t perform as expected?

The right partner can assess older units like manual matchplate or tight flask machines and help chart out a strong plan, one phase at a time. You’ll want someone who sees upgrades as part of your long game, not just a quick fix. They’ll ask smart questions, not just sell replacement parts.

It’s also smart to pick someone willing to collaborate throughout the process. From planning to post-install checks, their team should understand your goals and stay responsive. If they’re hard to reach or don’t get your production challenges, it might be time to look elsewhere.

Maintaining Peak Results After the Upgrade

Even the best upgrades won’t last if they aren’t maintained. Making those investments pay off comes down to how you care for them long term. A few smart practices can bring added value to every machine in your shop.

First, build or adjust your maintenance plan to reflect the new equipment. This might include tighter inspection cycles, software checks, or cleaning routines that weren’t needed with the old system. Even upgraded dies need to be broken in properly and inspected for early wear.

Next, keep your team refreshed on the new tech. If you’ve moved from manual to automatic controls, for instance, it’s easy for skill gaps to show up fast. Hold regular reviews or walk-throughs to make sure nobody gets left behind as systems evolve.

Here are some tips for keeping everything on track:

– Keep backups of any new software or control system updates

– Assign a team to stay up-to-date on available parts or add-ons

– Track performance data to spot any bad trends early

– Update operator handbooks every time tooling or features change

– Create a checklist specifically for any added automation

Finally, don’t let upgrades become a one-time fix. Look at them as steps that should fit into your overall production future. Regular reviews and minor fixes over time are better than running your machines to failure.

Better Performance With EMI Solutions

Whether you’re running older manual matchplate molding machines or investing in full automatic flaskless systems, the right upgrades can shift your output to a new level. From adding servo-driven controls to switching to energy-conscious components, even small steps can improve uptime, make staffing more flexible, and keep castings consistent. Over time, planning wisely, working with the right team, and keeping equipment well-maintained can make those upgrades deliver for years.

Change doesn’t have to be big to make a difference. Sometimes, fitting the upgrade to the problem is all it takes to give your molding machines a fresh edge.

Ready to take your production to the next level? By thoughtfully integrating updates to your molding machines, you can increase efficiency and reduce downtime. Explore how EMI’s range of molding machines can fit your unique needs. Whether enhancing precision or embracing new automation features, these investments can set your operations up for sustainable success.