Enhance Pattern Quality in Matchplate Molding

Pattern quality plays a big role in the reliability of matchplate molding machines. When patterns are damaged, misaligned, or worn out, the entire mold can shift out of spec. That can lead to issues down the line like poor surface finishes, dimensional inaccuracies, and misfits that affect how the parts function. It also adds stress to your production schedule, especially if you must rework or scrap entire molds.

That’s why keeping pattern quality in check isn’t extra—it’s part of running any efficient foundry. It keeps production flowing, minimizes waste, and helps maintain consistency from one job to the next. Failing to address bad patterns can slow everything down and cost more in labor, material, and energy than it would have to catch the issue early. Let’s take a closer look at what causes pattern issues, how to spot them, and what can be done to fix them before they disrupt your workflow.

Common Causes Of Poor Pattern Quality

Pattern quality problems don’t show up out of nowhere. They usually build up as small issues that aren’t addressed in time. Understanding the common causes is the first step toward solving them. These are the most frequent culprits behind pattern defects with matchplate molding machines:

– Inadequate maintenance and cleaning: Over time, residue and sand can build up in the machine and on the patterns, which causes surface damage and detail loss. Without regular cleaning, those small buildups can eventually lead to major flaws in pattern impressions.

– Wear and tear of molding materials: Patterns aren’t indestructible. With constant use, especially under high pressure and heat, the materials naturally degrade. That wear can cause deviations in shape and lead to less accurate molds.

– Misalignment in the machine setup: If the matchplate isn’t properly aligned or mounted, even a well-made pattern won’t function correctly. Misalignment can cause halves of the mold not to register accurately, which results in flash or mismatched parts.

– Inconsistencies in sand quality and mixture: Sand that’s too dry, too coarse, or inconsistently bonded can make it hard for the pattern to form clean edges and surfaces. Poor compaction can also affect how the pattern sets, leading to distorted or weak mold structures.

Each of these problems can impact quality and production time. Knowing what to watch for makes it easier to catch these issues before they escalate into something bigger.

Identifying Symptoms Of Poor Pattern Quality

Once bad patterns start affecting production, most operators will notice changes in how molds come out or how parts fit after casting. Catching these issues early lets you intervene before your operation is seriously impacted. Here are typical signs that pattern quality may be slipping:

– Molds have visible surface defects like pitting, lines, or blurring of fine detail

– Finished castings have uneven walls, irregular shapes, or inconsistent dimensions

– Scrap rates start to rise as defects become more common

– Machine logs or diagnostics report higher torque loads, misalignment errors, or unusual cycle times

– Operators report trouble getting clean releases or proper sand compaction on the pattern

For example, one foundry noticed that parts from their automatic matchplate molding machine were starting to come out misshapen. After some investigation, it turned out the matchplate had shifted slightly on the mounting points. A small tweak to the alignment fixed the issue and brought them back to spec with no need to stop production longer than a shift.

Staying alert to these warning signs can make a big difference, especially when pressure is high to deliver castings on tight timelines. Regular check-ins and clear communication between operators and maintenance staff can keep everyone ahead of these symptoms before they cause slowdowns or cost overruns.

Solutions To Improve Pattern Quality

Once the causes are clear and symptoms have been spotted, the next step is fixing the pattern quality issues before they dig into your production numbers. Most of these fixes aren’t complicated once they’re part of your regular process. It all comes down to good habits, dependable materials, and solid machine setup.

Start by adopting a consistent maintenance routine. Daily cleaning and checks on high-contact components help prevent buildup that leads to worn cavities and metal-on-metal damage. Schedule deeper inspections weekly or monthly based on usage, especially on key areas like the matchplate faces and alignment pins.

Here are a few quick wins to bring your pattern quality back on track:

– Inspect matchplates for nicks, dents, or warping before every shift

– Replace worn or cracked molds immediately, not after the next breakdown

– Use a dial indicator or laser tool to regularly check for proper plate alignment

– Track sand quality and moisture consistency with a repeatable testing method

– Keep tooling documentation up to date to identify recurring failure points

Material quality matters too. Using high-grade resins in core machines like vertical or horizontally-parted cold box systems gives more accurate detail and better durability. Machines such as dual station cold box units benefit from balanced wear since they operate in parallel. That kind of stability supports tight tolerances in production environments that can be busy and demanding without extra leeway for reworks.

Tighter sand control also improves pattern formation. If sands vary too much between batches or shifts, it’s tough to hold tolerance or repeatability. Binders and additives should be tracked with a reliable mix system. Small changes in blend or cure times show up fast in surface texture and dimensional defects.

Implementing A Quality Assurance Program

Having solid repair strategies is helpful, but prevention always beats fixing things after they’ve broken. That’s where a proper quality assurance structure can make a difference. It makes sure operators, supervisors, and maintenance teams all stay on the same page around pattern handling.

Each step in your workflow should include a simple and consistent inspection process. Start with checklists for startup and shutdown procedures, then add visual inspection points during production runs. Documenting criteria for pass and fail tolerances gets everyone looking at the same quality targets.

To make this work across the board:

– Train your team to know what good patterns and bad patterns look like

– Create a station log where operators can report defects in real time

– Build feedback loops between operators, tooling staff, and supervisors

– Use basic diagnostic tools like surface gauges and pressure monitors

– Review rejected castings as a group to trace root causes and avoid repeats

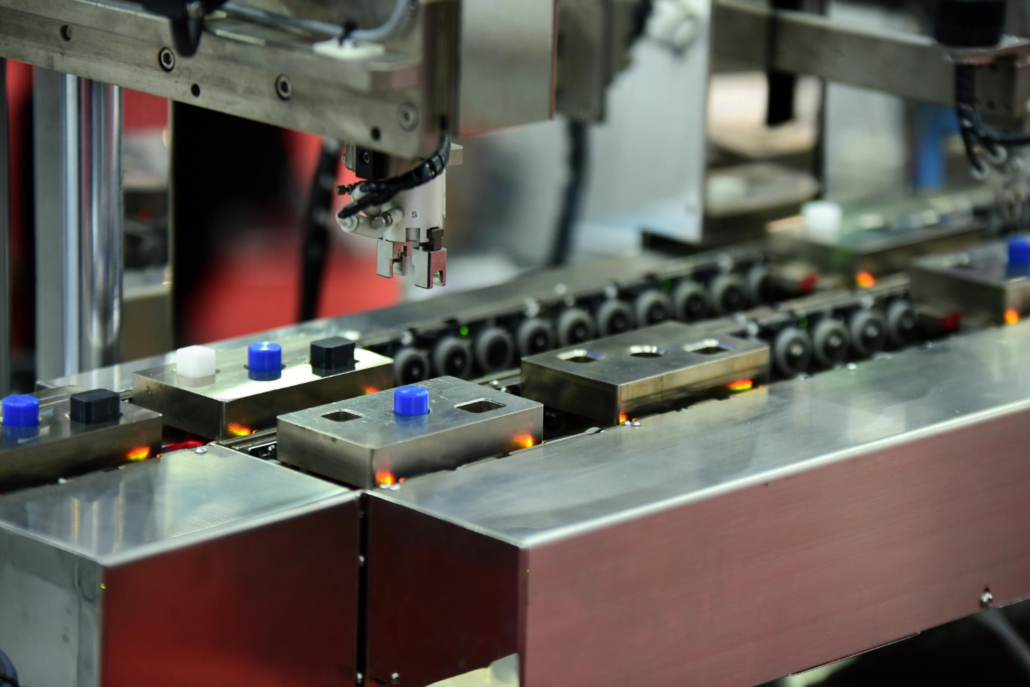

Advances in machine technology also add value here. Some molding machines allow integrated diagnostics and usage tracking. This can help teams spot patterns in downtime, sand flow inconsistency, or pressure failure. Systems like automatic flaskless matchplate machines will often alert you to those shifts and give you time to react before scrap parts show up.

Reliable Practices that Keep Your Foundry on Track

Solving one pattern issue won’t take care of everything. It’s sustained attention and small incremental checks that build into long-term dependability. Whether you’re working with big flask systems or compact prototype molds for short runs, every team benefits from clean starts and steady controls.

Keeping your shop efficient doesn’t have to mean big investments every time. Many improvements for pattern quality come down to planning ahead and knowing where weaknesses tend to creep in. When the team is aligned, processes stay repeatable, and the gear runs like it should, your line becomes more predictable.

Reliable castings begin with clean, accurate patterns. With the right habits and tools in place, foundries can focus more on output and less on fixing preventable errors. Getting ahead of pattern issues saves more than time—it protects your reputation, builds trust with clients, and keeps your floor running at full pace.

Ensure your casting operations stay consistent and efficient by focusing on repeatable quality at every stage. At EMI, our solutions such as molding machines are built to support tighter tolerances and smoother workflows. With the right setup and equipment, you can reduce downtime, cut back on waste, and keep production moving without interruption.